#Product Trends

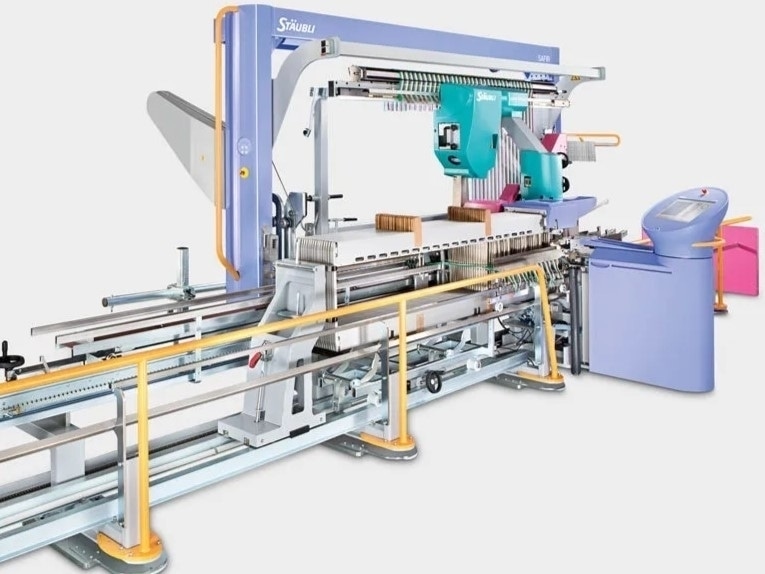

Drawing-in machine with fast and reliable style change | Stäubli textile

Discover the unmatched speed and efficiency of Stäubli's SAFIR PRO S67 drawing-in machine

High speed drawing-in of cotton warps

With up to 200 yarns drawn-in per minute, the SAFIR PRO S67 supports utmost productivity in the drawing-in department of weaving mills producing shirting, men’s suits, or home textiles.

Fully automatic Layer- & Offset-Management

Stäubli offers the new Layer- & Offset-Management option for double warp beam applications for staple fibre, and especially fancy denim applications on the stationary drawing in machine SAFIR PRO S67.

Stäubli doubled the number of clamping rails in the yarn frame in order to handle each yarn sheet with two clamping rails. The yarn sheets are now clamped independently by a double clamping system made of 4 clamping rails. The offset is corrected fully automatically.

The machine brings the two yarn sheets into perfect alignment with zero offset. This allows the yarn sepa- ration unit (suction nozzle) to process the yarn layer without time loss.

The machine operates efficiently with no need to move to an offset yarn. The horizontal offset movement is obsolete. In this way, the new option permits the highest

performance.

Faster than the human eye: AWC 2.0 colour nuance detection

The essential function of our state-of-the-art AWC 2.0 technology is interpreting the measured data through image processing & data analytics, using advanced algorithms & software and high-performance proces- sors.

This allows the determination of titre, colour, twist direction, and, within certain limits, even hairiness, transparency, and monofilament or multifilament char- acteristics. For multi-coloured warps, AWC 2.0 can detect a great number of colour nuances per warp. This gives mills expanded capabilities to produce innovative, outstanding, and unique designs.

A quality weaving process

With SAFIR and Active Drawing-In Control 2.0, your processes are optimized and your completely drawn-in weaving harnesses will be available on time, in the

desired quality, and ready for quick startup of the down- stream weaving process.

“We are looking forward to our new investment in Stäubli SAFIR PRO S67 which will set a foundation for a smooth and efficient weaving process, leading to high-quality fabric production and quick adaptation to market needs.”

Mr. Zekeriya Tanrıverdi

Member of the board

The weaving company Lutuf Mensucat A. Ş is currently running 248 weaving machines. The daily production output in average is 50.000 meters. In order to answer the various market demands, Lutuf always invests into the first-tier high performance machinery with high speed.