#Product Trends

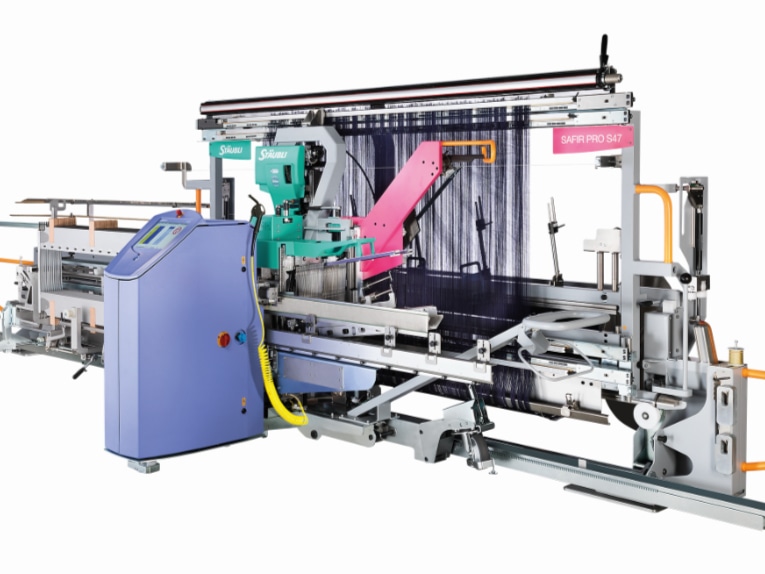

Drawing-in machine SAFIR PRO S47 | speed and quality

High speed automatic drawing-in machine SAFIR PRO S47 ensures speed, quality, and reliability in automated fabric processing, maximizing productivity and flexibility for diverse textile applications.

The drawing-in department becomes the quality driver of the weaving mill

Weave structures have evolved enormously in recent years. Today’s fabrics must meet the highest standards for use in the construction industry, environmental protection, medical technology, and aircraft and automobile manufacturing. International fashion fairs are being held increasingly often, forcing weaving mills to produce the required fabrics quickly and in top quality. This requirement can be met only if the warp yarn is drawn into the weaving harness in the weaving preparation department actively, automatically, and with perfect sequence.

Yarn recognition is the key

With our automatic drawing-in machines SAFIR PRO featuring AWC 2.0 for optical, non-contact recognition and measurement of yarn properties, Stäubli has set standards for the automatic drawing in of warps – providing impeccably prepared weaving harnesses. Sophisticated algorithms and cunning software enable fast, error-free, automatic feeds – all supported by smart sensors and optics. Measurements are made when the individual yarn is separated from the warp sheet and ready to be drawn in. Based on the measured data, AWC 2.0 controls the subsequent steps of the drawing-in process.

Offset management for double warp beam application

Stäubli offers the new Layer & Offset Management option for double warp beam applications for staple fibre, and especially fancy denim applications. The offset is corrected fully automatically. The machine brings the two yarn sheets into perfect alignment. This allows the yarn separation unit to process at optimized efficiency.

Digital integration

With SAFIR PRO S47 weaving mills profit from a connected production solution that helps you to enhance the workflow and supports greater freedom in your production. SAFIR machines can be digitally integrated in your ERP/MES system. This makes you safe additional time and enables you to focus on your strengths. In the meantime SAFIR PRO S47 prepares your completely drawn-in weaving harnesses on time, in the desired quality, and ready for quick startup of the downstream weaving process.

Workflow optimization

This mobile drawing-in machine serves ideally two or more stationary drawing-in stations. This is comparable to a traditional, non automated mill organisation, were one person is dedicated to the warp preparation besides the weaving machine. SAFIR PRO S47 offers ease in use and easy handling. Combined with its perfect drawing-in quality, this machine supports best efficiency in the downstream weaving process.