#Industry News

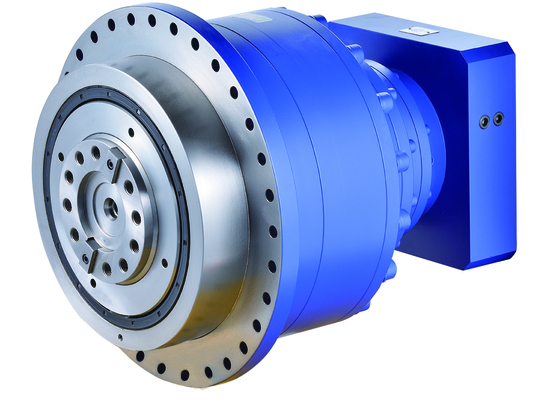

Root cause of abnormal noise in planetary gear reducers (1)

Here is what we think noise might occur when machining.

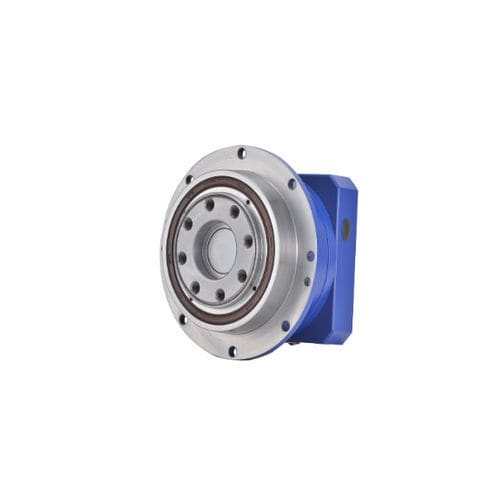

1) Low contact ratio of gear: noise is likely to cause during transmission when contact ratio of gear is low. Core parts in the gear parameters are correlated to gear design.

2) Accuracy of gear: accuracy of gear and noise level are highly associated with each other. The higher the gear precision is, the denser the contact area marks will be. If contact marks are visible on the entire tooth surface, the noise level will be lower as expected. If, however, the gear precision is low, the surficial area will be smaller, and the noise level will be relatively high when the gears cannot be completely matched on the contact surface, resulting in collision and unstable operation.

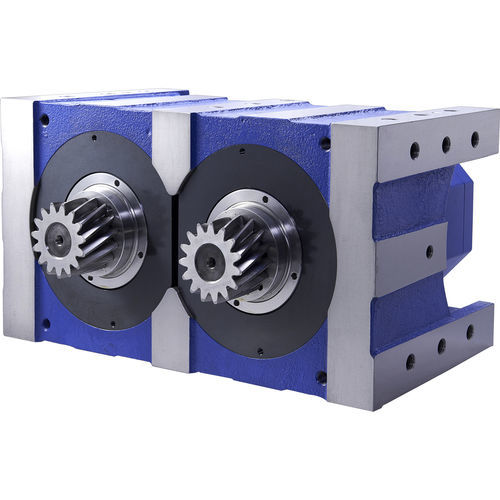

3) Errors caused by machining: Both the pitch error and the profile error may cause noise during machining. The pitch error occurs mainly due to the misalignment of the rotation axis of the gear and the ring gear; the profile error, on the other hand, is caused due to the asymmetry of the tooth caused by the error generated when either one of the hob, the cutter and installation is problematic, which further leads to the unsteady transmission. Vibration, undercutting and collision are typically identified as the major issues of excessive noise.