#Industry News

JONO’s MSW Solution

Zichuan Solid Recovered Fuel (SRF) Plant Project

Project Overview

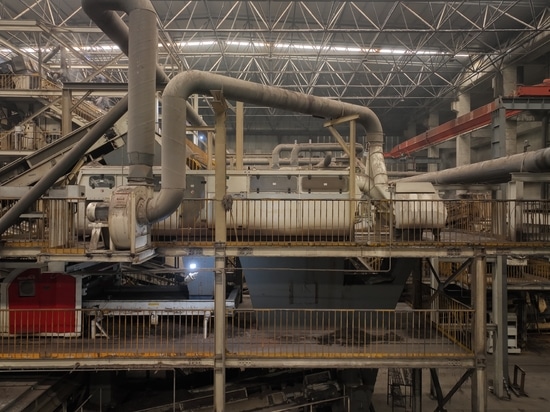

The Zichuan Solid Recovered Fuel (SRF) Plant Project is a mechanical pre-treatment facility for mixed municipal solid waste before incineration. It processes 1,000 tons of waste daily using two-stage shredding and mechanical separation to sort ferrous metals, non-combustibles (e.g., glass, stones, ash), and combustibles.

In this project, JONO has implemented its advanced crushing technology to process combustible materials into solid recovered fuel (SRF) with an average particle size of approximately 80mm which improves combustion efficiency.

Project Highlights

Advanced Two-stage Shredding Pre-treatment

The project features a highly efficient two-stage shredding system including equipment like Aries Primary shredder which ensures the combustible waste is reduced to the ideal size. This process optimizes the quality of SRF and enhances its suitability for incineration.

Efficient Mechanical Separation

The plant integrates a mechanical sorting system to recover valuable ferromagnetic metals, which can be recycled, and to remove non-combustible impurities such as glass, stones, and ash. These recovered metals, commonly sourced from discarded appliances, construction materials, and packaging, are then sent to smelting facilities for purification and reuse in manufacturing cycles. This makes the SRF better in quality and keeps the boiler from building up too much residue.

Optimized SRF Production

By producing Solid Recovered Fuel (SRF) with a controlled particle size of approximately 80mm, the project ensures better combustion performance. The uniform fuel size contributes to more stable furnace conditions, improving combustion completeness and reducing unburned residues.

Conclusion

The Zichuan SRF Preparation Plant plays a crucial role in optimizing waste-to-energy processes by efficiently converting mixed municipal solid waste into high-quality fuel. Through its advanced crushing and separation technologies, the facility not only enhances combustion performance but also supports environmental sustainability. By integrating innovative pre-treatment solutions, this project sets a benchmark for the efficient and eco-friendly utilization of municipal waste in energy generation.