#Product Trends

Digital drilling rig

Monitoring of drilling rig

- Remote monitoring of operating parameters

- Prevention of equipment idling

- Fuel consumption monitoring

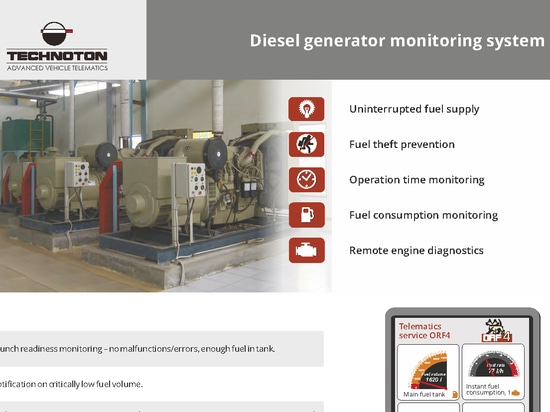

Technoton’s solution “Digital drilling” is designed for performance evaluation and optimization of drilling rig’s power units (diesel generator sets) and remote monitoring of drilling rig’s engines. Drilling rig monitoring system allows to increase operational efficiency of drilling rig, reduce maintenance costs and prevent failures of power units.

Extended information on fuel volume in tanks, fuel consumption and engines’ operation time in various work modes is gathered using smart-sensors such as DUT-E fuel level sensor and DFM fuel flow meter. Basic data from standard rig sensors (temperature, rotation, pressure) is collected using MasterCAN DAC configurable i/o module. All data is sent over CAN j1939/S6 interface to CANUp online gateway and later transferred to web-based monitoring platform.

“Digital drilling” significantly simplifies data collection and processing, allows to ensure continuous operation of power units, implement predictive maintenance approach and increase entire efficiency of drilling rig operation.