#Industry News

How To Address PCB Heat Dissipation Issues

PCB Heat Dissipation Solutions

In the operation of electronic devices, the PCB, as the carrier supporting various electronic components, has its heat dissipation performance directly impacting the stability and reliability of the entire system. With modern electronic devices evolving towards high performance, miniaturization, and integration, the issue of PCB heat dissipation has become increasingly crucial. Based on TECOO's many years of experience in electronic manufacturing services, this article delves into the causes, impacts, and a series of effective methods for addressing PCB heat dissipation issues.

I. Causes Of PCB Heat Dissipation Issues

High Component Density: With the miniaturization of integrated circuits, the component density on PCBs has increased, leading to a rise in heat generation per unit area.

Increased Power Consumption: The use of high-power components such as high-performance processors and power amplifiers has significantly increased the overall power consumption of PCBs, making heat dissipation more urgent.

Space Limitations: Miniaturization designs have severely limited the space for heat dissipation on PCBs, making traditional cooling methods such as fans and heat sinks difficult to apply.

Poor Heat Conduction: The thermal conductivity of PCB substrates is limited, making it difficult for heat to quickly transfer to the external environment.

II. Impacts Of PCB Heat Dissipation Issues

Performance Decline: In high-temperature environments, the performance of electronic components can be affected, such as slower processor speeds and shortened component lifespans.

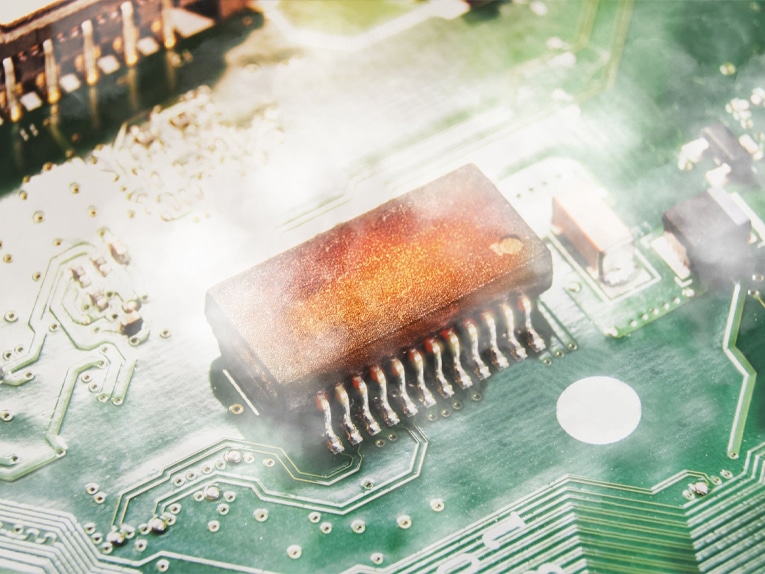

System Instability: Excessive temperatures may lead to component failures, potentially causing the entire system to crash.

Safety Hazards: Long-term operation at high temperatures may pose safety hazards such as fire risks.

III. Strategies For Addressing PCB Heat Dissipation Issues

Optimize PCB Layout:

Reasonably distribute high-power components to avoid localized overheating.

Use thermal simulation software for preheating analysis to optimize component layout and wiring, enhancing heat dissipation efficiency.

Select High-Thermal-Conductivity Materials:

Choose PCB substrates with high thermal conductivity, such as aluminum-based or copper-based materials.

Use auxiliary materials like thermal pads and thermal adhesives in critical areas to improve heat transfer efficiency.

Increase Heat Dissipation Structures:

Design heat dissipation slots and fins on the PCB to increase the heat dissipation area.

For miniaturized devices, consider using advanced technologies such as micro fans and liquid cooling.

Utilize Natural Convection:

Through rational design of the PCB's shape and layout, utilize natural convection of air for heat dissipation.

Set ventilation holes at the edges of the PCB to improve air circulation efficiency.

Implement Thermal Management Strategies:

Monitor system temperatures and adjust system power consumption based on temperature changes for dynamic thermal management.

Use temperature sensors such as thermistors to monitor and provide real-time temperature feedback.

Consider Environmental Factors:

Fully consider the device's operating environment, such as temperature and humidity, during the design phase.

Design targeted cooling solutions for specific environments.

PCB heat dissipation is a significant challenge in modern electronic device design. By optimizing layout, selecting high-thermal-conductivity materials, increasing heat dissipation structures, utilizing natural convection, implementing thermal management strategies, and considering environmental factors, we can effectively address this issue, ensuring the stable operation and long-term reliability of electronic devices.