#Industry News

Raising the Ergonomics Bar with Smart Electric Actuators

Electric linear actuators have long delivered ergonomic benefits by automating tasks that are repetitive, dirty, or dangerous.

Recently, the integration of onboard intelligence into electric actuators has raised their ergonomic contribution to a new level. Smart features such as digital motor control, position feedback, synchronization, and real-time monitoring make it even easier to apply automation to improve workplace comfort, safety, and efficiency.

Digital Motor Control

Traditional actuators often depend on large, power-inefficient relays or independent controllers to extend, retract, or halt the actuators. Using onboard electronics to manage the power can reduce current at the switches or contacts from 20A to under 22mA, enabling a simpler, less expensive system design. Operators can run and change actuator direction off of a simple control.

Imagine, for example, a workspace in which workers are handling components weighing more than 100 pounds and requiring frequent reaching and bending. If their worktable was controlled by actuators equipped with low-level switching, each user could adjust the height to a level that requires minimal bending or stretching, reducing fatigue while also improving productivity. (Figure 1)

While traditional actuator assemblies might allow such adjustments, they would require external motor switching, which draws more power and must be done manually. By controlling the circuit flow electronically, however, all such switching is embedded in the actuator housing, which also provides a sleeker, cleaner setting devoid of external wiring.

Automating motor switching has safety benefits as well. An actuator draws between 20 to 40 amps depending on the load. Minimizing exposure to this current during installation and operation enables greater ergonomic control, while reducing potential shock hazard risks from high amperage relays.

Digital position feedback

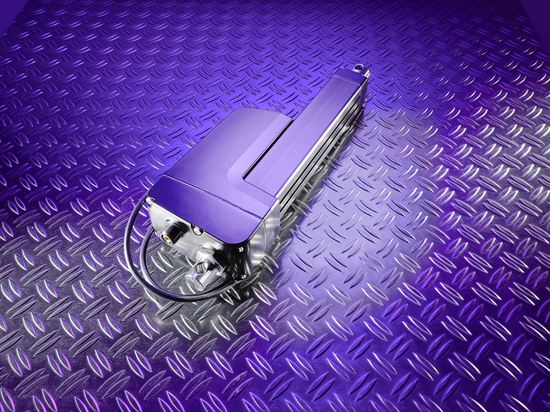

Smart electric actuators (Figure 2) not only enable fine position adjustments, but they also provide real-time feedback on the extent of those adjustments. They can report on the location of the load throughout the stroke. In the above worktable example (Figure 1), they could capture data on the location of the load and compare it to pre-set parameters to ensure consistent operation.

Alongside digital position feedback comes the ability to measure and control the speed. Suppose you are automating the raising or lowering of a heavy door that shields a particular machine or forms a partition. The microcontroller could receive pulse counts from an encoder and calculate travel distance and speed based on the number of pulses received within a set time interval. Staying with the heavy door example (Figure 3), this would enable setting the speed to slow down as it reaches the end of the stroke, preventing the door from slamming shut before the operator has time to clear the opening.

Analog position feedback

Digital position feedback is one of the easiest ways to measure actuator speed, but it is not easy to program because it does not remember the positions it reports after a power loss or shutdown. Smart actuators equipped with analog potentiometers, however, can receive exact position information from potentiometers in the actuator gearbox, which sends voltage signals that alert users of the drive speed and direction – from beginning to end of the stroke. They remember that position, so if power is lost, there is no need to return to a home position and reset the device.

Reliable position memory enables the development of applications that store ergonomic settings for each user, allowing the workspace to be tailored to multiple individuals based on factors such as height, stored procedures or user preferences.

Synchronization

The ergonomic benefits of smart electric actuators are even more pronounced when used with multiple actuators. You can set actuators to adjust automatically to shifting loads. An aircraft assembly application in which five or ten workers are finalizing the fuselage, for example, might support them with a platform that must be raised high above the ground. As workers move about the platform, the weight shifts to different parts of the platform, which causes potential imbalance. Smart actuators located at various points under the platform, (e.g., one on each corner) could be set to self-adjust to compensate as the load shifts during synchronous actuator movement. (Figure 4)

Making adjustments that counteract these shifting loads is done with both speed control and positioning feedback. Actuators communicate with each other across an internal network, read each other’s speed based on positioning feedback, and adjust accordingly.

Doing so with digital feedback, however, results in a stuttered step, which designers can avoid by putting both position and speed in the feedback loop and having them adjust based on the speed of actuation and the position. This provides an ergonomic benefit that will lift a shifting load smoothly from multiple points, compensating for awkwardly sized loads such as platforms, seats and heavy doors.

Controlling multiple traditional actuators is possible, but is an imprecise, time-consuming and labor-intensive operation that places additional strain on the actuators, eventually leading to binding or other malfunction. Smart actuator synchronization removes the guesswork and results in a balanced, smooth and well-positioned movement.

Real-time monitoring

Smart electric actuators can return ongoing monitoring results for temperature, current, speed, voltage and other variables, which enables advanced condition monitoring, diagnostics and error handling. Feedback can appear as quickly as ten times a second, as the actuator continuously tests itself. If it detects a problem (e.g., surpassing a temperature threshold), the actuator can stop mid-stroke or finish its programmed move – either fully retracted or extended – stop, and send an error flag to the computer, all in a fraction of a second.

Such feedback enables users to step back from their operations to analyze patterns in usage, speed and position to make operations more friendly, safe and efficient. This is especially valuable in factory automation settings that integrate multiple devices (Figure 5). Collected data might show how many times a workstation has been raised and lowered or how many times a door has been opened and closed. This can be compared to operating history or industry best practices to improve the cell design.

Operating data might also be cross-tabulated with injury reports, which can point to the need for more ergonomic analyses. If an actuator positioning a Crimp Die was constantly reporting overloads, for example, it might indicate an incidence rate of people hurting themselves and could identify at which cell this is happening, what time of day and which shifts may be impacted.

Diversify to survive

The many features built into smart electric actuators allow users to approach an application with design simplification in mind. Having the ability to control the actuators through digital means, provide digital or analog feedback, allow for multi-actuator synchronization, or adding real-time monitoring for metrics provides the tools necessary to get the job done in one package. Now when users look at an application, they can deliver an automation solution that goes beyond the basic functionality of a back-and-forth movement. Smart electric actuators provide plug-and-play movement across multiple axes of automated processes without the complications of other automation technologies, such as hydraulic or pneumatic cylinders. By reviewing the application needs beforehand, the user may well find that the smart actuator’s ability to control movement, remember position or provide application metrics can differentiate itself amongst a sea of other technologies.

As machine builders and end users alike look to the future, their automation solutions will go beyond that of basic functionality and continue to provide easier solutions, longer equipment life and long-term safety.

The more intrinsic this control capability is to the equipment, the less it stands between the user and the ultimate benefits they expect. The payoff can be found in worker satisfaction, safety, health and productivity ̶ all of which benefit everyone in the value stream.