#Industry News

The single-material solution from TTZ

Alternative methods of heat exchanger production - the ZD way from TTZ

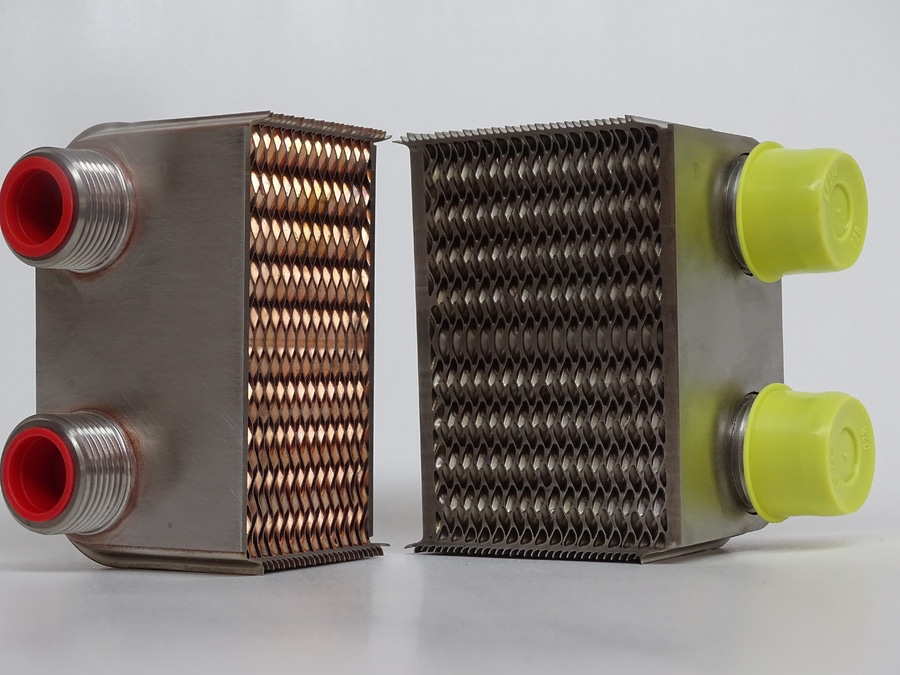

Millions of brazed plate heat exchangers are produced every year - indispensable components that play a key role in heat pumps and therefore in the energy transition. The conventional manufacturing process for heat exchangers made of stainless steel and high-purity copper makes the recycling process more difficult. The soldering process produces solid units that cannot be separated economically later on, meaning that stainless steel is “contaminated” by copper in the recycling process. Why is this problematic?

Recycling quality: Up to 80% recycled material is used to produce high-quality stainless steel. However, too much copper makes recycling more difficult and impairs the quality.

Copper demand: Thousands of tons of copper are removed from the recycling cycle every year - a valuable raw material that is urgently needed in electrical engineering, digitalization and renewable energies.

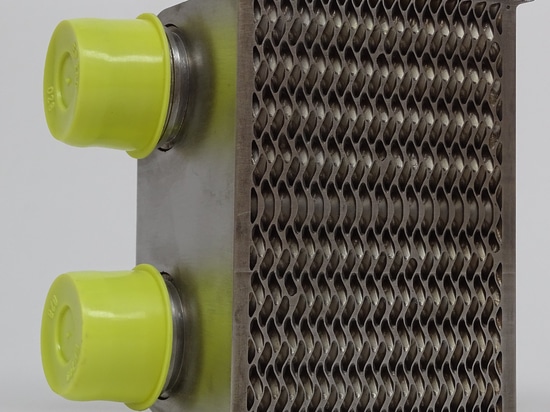

With the ZD series, we offer a heat exchanger made from fully recyclable stainless steel. This solution helps to preserve copper stocks in the recycling loop and combines sustainability with efficiency - an important contribution to conserving resources.

A sustainable future requires new approaches.

Discover with TTZ how innovation makes the difference.

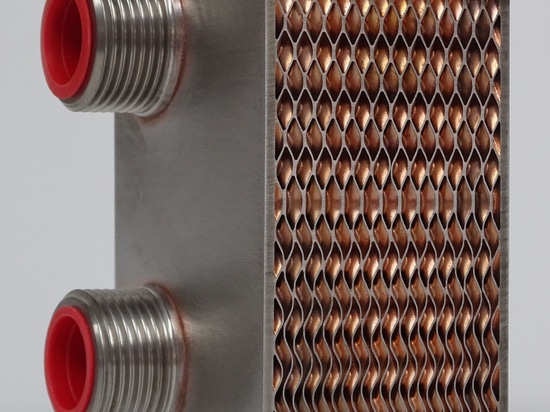

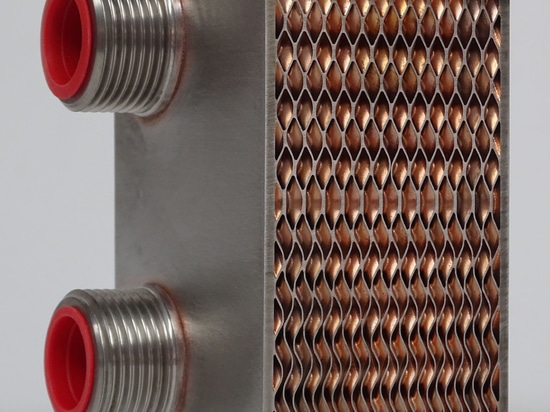

Image: left variant with copper, right ZD series made entirely of stainless steel