#Product Trends

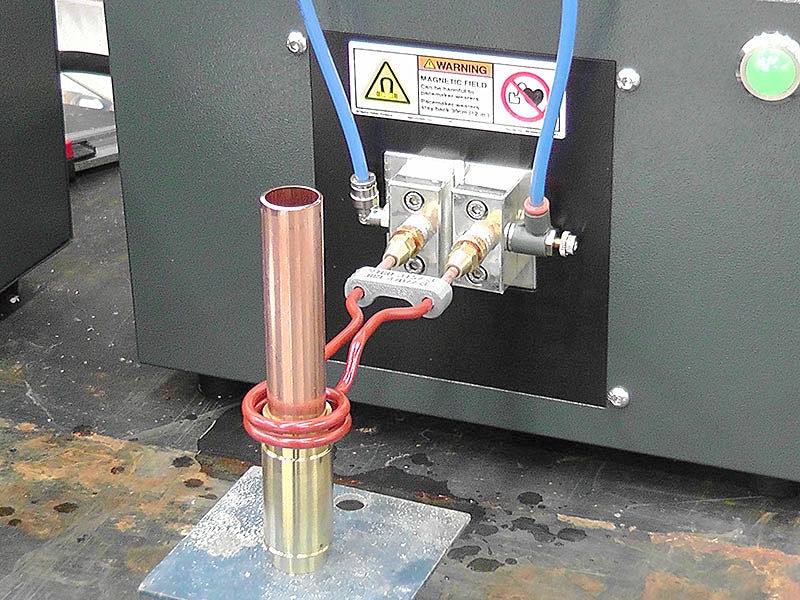

Induction brazing of copper tubing and brass fitting

Equipment

UltraFlex UPT-S5 Ultraheat 5 kW

HS-8 Heat Station

2 Turn Helical Coil

Materials

• Brass Fitting

• Copper Tubing

• Silver Brazing Alloy (pre-formed)

• Flux

Temperature

Approximately 1350 °F (732°C)

Temperature

Approximately 1350 °F (732°C)

Process:

1.The copper tubing and brass fitting were assembled together.

2.A pre-form of the silver brazing alloy was seated above the joint, and flux was added.

3.The assembly was placed the two-turn helical coil, and positioned so the targeted joint

was centered in the coil.

4.60 seconds in the coil, the brazing was complete.

5.The material was cooled in water following the completion of brazing.

6.The joint was then cross-sectioned to validate that the brazing process had produced a strong, high quality joint.

Results/Benefits: Induction heating provides:

* Strong durable joints

* Selective and precise heat zone, resulting in less part distortion and joint stress than welding

* Less oxidation

* Faster heating cycles

* More consistent results and suitability for large volume production, without the need for batch processing

* Safer than flame brazing