#Product Trends

Capacitive level measurement technology for full detection of crude oil in tyre production

For the implementation of a reliable level limit measurement within lubricating oil pipelines of tyre production, the limited space situation as well as high material viscosity had to be considered in particular.

Level limit measurement in pipelines with lubricating oil

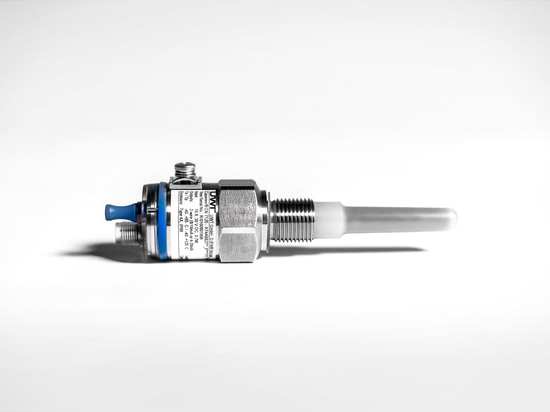

One of the largest global tyre manufacturers needed a reliable point level sensor to measure the level in a 3" tube with lubricating oil in their subsidiary in Argentina. Due to the viscosity of the material, not every measuring principle works in this installation situation. The crude oil has a DK value between 2 and 3, the process pressure can be up to 0.8 bar (11.6 psi) and the process temperature up to 80 °C (176 °F). In addition, there is a high moisture content with condensate within the atmosphere. In this case, the ideal solution was UWT's Capanivo® CN 7000 capacitive point level sensor. The sensor has a ½" stainless steel thread and a PPS probe. The integrated active build-up compensation prevents incorrect switching due to material adhesion around the probe. Its reduced installation length ensured optimal implementation within the 3" pipe. Together with the local partner KDK - CIA ARGENTINA DE CONTROL AUTOMÁTICO on site, the capacitive level switch was installed in the sides of the stainless steel pipes according to full signal detection. Vibration and electrostatic charging did not have to be considered in this application.

Capacitive full detection with the Capanivo® 7000 in pipelines with lubricating oil:

Compact limit switch with ½" connection thread

"Active Shield" and "Tip Sensitivity" technology in case of material adhesion

PPS probe

International certifications

Maintenance-free sensor