#Industry News

Industry Award 2017

for the protection plus model from RFnivo

Protection Plus with innovative corrosion protection

Capacitive RF probe with full coating protection

In power plants, the demands made on the fill level sensors can be very high due to the fact that the sensors come into contact with aggressive media such as sulphur oxides, heavy metals or even acids. Where limit switches are used for dust detection in flue gas cleaning, they need to be robust enough in order to deliver reliable and consistent performance. Often maintenance costs or replacement of these sensors can be very high due to their quality not being adequate to meet the demands and so they achieve only a short operating life. This is particularly evident in measurement tasks in flue gas cleaning within waste incineration plants.

Longer service life due to increased corrosion resistance

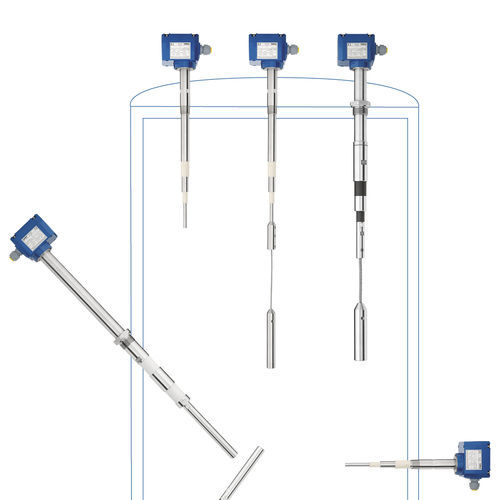

UWT has further developed the RFnivo® 3100 capacitive level limit switch for this type of measurement task in the dust extraction of flue gases so that it meets and withstands the demanding conditions. All process-contacting parts of the sensor have been designed to be completely corrosion-resistant. Firstly, the RF boom is coated with PFA Teflon® and, secondly, a section of the process connection thread has been completely made of PTFE so that all parts in contact with the process are fully corrosion-protected.

Probe boom with PFA full coating

The shaft of the RFnivo® limit switch is fully coated with PFA Teflon®. It is resistant to almost all chemicals and can withstand high temperatures. In contrast to a spray coating, the type of coating of the RF probe is much more resilient, up to 1.5mm thick, and thus has more protection in abrasive applications.

The RFnivo® 3100 with fully coated probe boom can be made with a boom length from 200mm up to 1500mm and can therefore be used in a variety of installations.

Process connection thread made of PTFE

In order to ensure full and comprehensive protection of the process-contacting probe extension the process connection thread, which is connected to the boom, is made completely from PTFE Teflon®.

In plastics, PTFE is the material that offers most resistance to most basic chemicals. Apart from liquid sodium and fluorine compounds, PTFE is resistant to almost all media even at higher temperatures. Corrosion on the thread itself is thus reduced by a special design using Teflon®. Due to the extremely low surface tension of PTFE, no dust-like materials from the flue gas filters stick to or cake the process connection thread. In addition, the capacitive RF limit switch already offers a particularly high load capacity in the standard version. If overpressure is present in the process tank, this can be up to 25 bar for and still the RF probe will operate.

Advanced technologies for flue gas dust extraction

The capacitive fully-coated RF sensor is a new safe solution for all systems where applications with a particularly aggressive process environment exist. This is, for example, wherever flue gas cleaning takes place. In addition to waste-to-energy plants, this situation applies to biomass plants, peat and coal power plants. Improved corrosion protection of measurement sensors in certain processes for flue gas cleaning is an important topic for sludge combustion in chemical plants as well as for sawmills with integrated incineration plants for the production of energy.