#Industry News

Smart Gearbox: re-thinking technology for progress

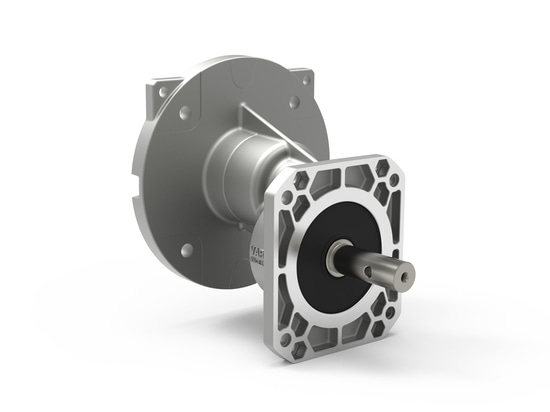

Thanks to an in-depth understanding of the market, applied research and constant experimentation, Varvel has designed a new gearbox capable of functioning without lubricant, a totally unprecedented solution to one of industry's most challenging probl

The Bologna-based Varvel Group, specialists in the design, production and sale of power transmission systems, has been a global byword for Italian precision engineering for over 60 years.

Thanks to its success in Horizon2020, European Framework Programme for Research and Innovation, after passing of Phase II, the Group was awarded funds for the ambitious project of the Smart Gearbox, the gearbox of the future.

The mechanical gearbox is a mature product with countless applications in many industries. Nonetheless it still suffers from one particular defect to which no solution has ever been found, until now: lubricant leakage.

Gearboxes use metal gears enclosed in a metal casing to generate a different speed at the output to that at which the input shaft is driven. Conventional gearbox components are extremely wear resistant and able to withstand significant strain. The only weak point in the gearbox lies in the seal rings around the input and output shafts. These are made from rubber, a far softer material than metal and one more susceptible to wear and attack by atmospheric agents. Over time, seal rings deteriorate and allow lubricant to leak out of the casing.

In applications that require a sterile production environment or strictly controlled hygiene and sanitary conditions, as in pharmaceutical, biomedical and food processing industries, even the smallest oil leak can require a machine to be shut down immediately, with instant loss of production.

It was with these applications in mind that Varvel decided to develop a solution capable of eliminating once and for all the problem of oil leaks: a gearbox with guaranteed performance capable of running without lubricant in controlled temperature environments and high hygiene production conditions.

Varvel completely redesigned the gearbox, starting from its raw materials. The only way to eliminate all risk of lubricant leakage was to eliminate the lubricant itself, but this was simply not possible with metal gears.

Varvel is developing a worm gearbox capable of transmitting power effectively without lubricant in which the gears are made entirely from advanced thermoplastics with specially enhanced tribological properties, and to do so choose to use self-lubricating thermoplastic materials with added carbon fibres.

The new gearbox will be entirely maintenance-free: once installed it will be able to function continuously throughout its working life. The use of plastic gears also eliminates the need to dispose of spent lubricant, and therefore makes a major contribution to reducing impact on the environment.

“Varvel's new gearbox – says Elena Ferramola, development and testing Manager, from Varvel’s R&D Department - is designed to offer an effective and sustainable solution to one of industry's toughest problems. Implementation of Varvel's new technology in self-lubricating plastic materials leads to improved productivity and reduced environmental impact in food and biomedical production processes. Varvel's new gearbox represents major technical progress as it maintains the most useful characteristics of conventional gearbox technology while innovating for the benefit of precision engineering. There is simply no other way of describing it: it's a Smart Gearbox!”