#Product Trends

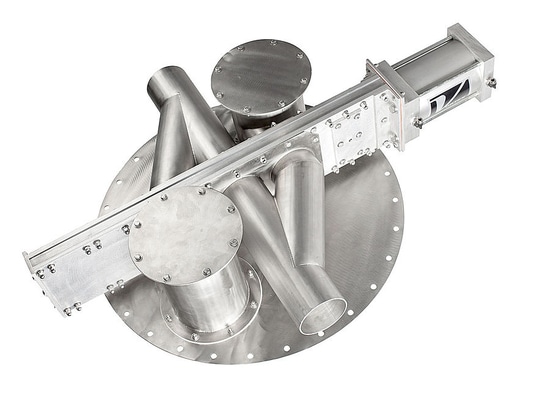

Vortex Gravity Vee Diverter for Simultaneous Flow or Shutoff

While traditional “A” valves or flop gates require an additional knife gate above the valve to be shut off material flow before redirecting the material, Vortex''s dual slide gate design allows for individual actuators to independently control material flow through each outlet. The Gravity Vee is also capable of metering flow through either outlet port.

Vortex''s dual slide gate design eliminates internal ledges where material can lodge or remain trapped, minimizing material cross contamination or spoilage. The self-cleaning action of the sliding blade removes material and eliminates material sticking unlike traditional flapper diverters. The Gravity Vee also features removable access ports to replace the bonnet seals while the diverter remains in service.

Flop gate or "A" diverters require clearances to operate allowing leakage of fine materials beyond the closed post. The "live" loaded net running seals in the Gravity Vee Diverter provide a positive material seal across the closed port(s).

The Vortex Gravity Vee Diverter can be custom made with modified sizes, construction material, and port configuration. For more information on Vortex''s Gravity Vee Diverter, visit our website at www.vortexvalves.com or email us at vortex@vortexvalves.com.