#Product Trends

Use of hydraulic position sensors in brake force measurement

Inspecting vehicle brake force is absolutely essential, as brake force is a critical safety factor in road traffic. It decisively affects a vehicle’s ability to slow down or stop in time and prevent potential accidents, so it’s essential for it to be checked regularly.

Brake force inspection is a key component of vehicle maintenance. Several million brake force inspections are performed every year in Germany. These inspections are carried out in workshops, as well as at testing organisations and test centres, to ensure that vehicles meet the legal requirements and that the safety of all road users is guaranteed. The economic significance of these inspections is not to be underestimated. In Germany alone, the cost of the services associated with these inspections amounts to several million euros per year.

The brake force inspection business has a promising economic outlook. In light of the growing number of vehicles on the road and the increasing number of road safety regulations, the demand for reliable car lifts and associated services is expected to continue growing. This presents new opportunities for companies that invest in the development and distribution of car lifts, as well as workshops and testing organisations that offer these services.

To ensure that vehicles are able to brake effectively, car lifts are used which enable precise measurement of brake force. However, the measurements come with their own challenges. To ensure accurate results, vehicles need to be held on lifts so that the wheels can rotate unimpeded and the brake force can be measured. Various factors have to be considered here, such as the weight of the vehicle as well as the condition of the tires and the brake system It is also important to ensure the correct alignment of the vehicle on the lift to ensure accurate results.

Brake force measurement is usually conducted as part of the TÜV general inspection. There are various methods of measuring brake force, but one of the most common is the use of a brake test stand.

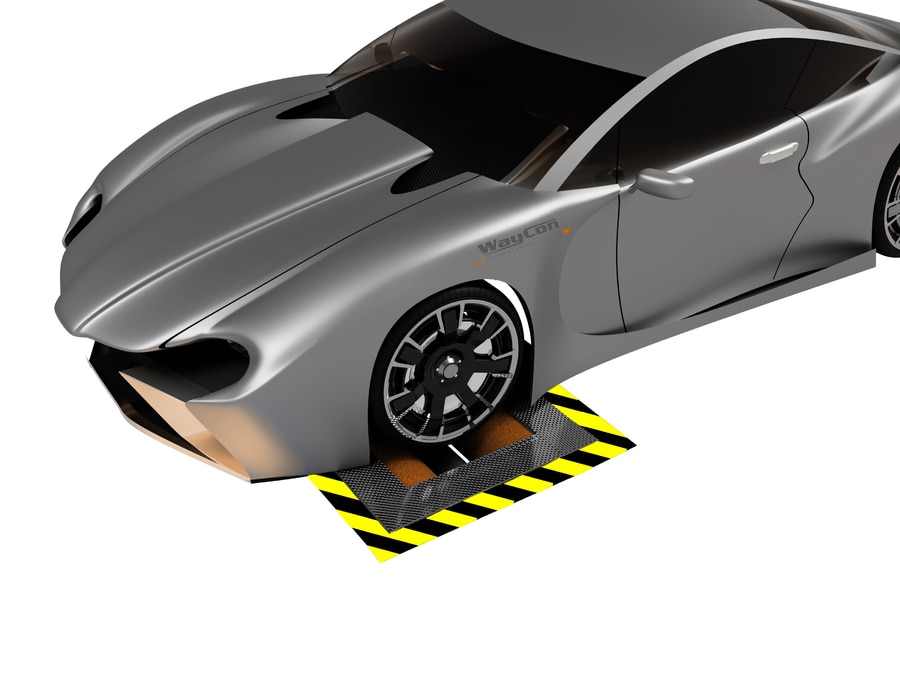

A brake test stand usually consists of the platform on which the vehicle is placed, plus two or more rollers which rotate under the wheels. The vehicle is positioned in such a way that the drive wheels rest on the rollers while the other wheels remain suspended in the air. The rollers are raised using hydraulic cylinders which use WayCon magnetostrictive hydraulic position sensors. These monitor the elevation of the rollers to ensure that they can rotate freely. Lengths up to 100 mm are most commonly used. The MAZ magnetostrictive position sensor was developed specifically for this kind of application. The stainless-steel housing of the hydraulic sensor is suitable for operating pressures of up to 350 bar. The sensor operates in line with the wear-free magnetostrictive measurement principle, resulting in a long lifespan. With a measurement range of up to 2.5 m and accuracy of ±0.02%, the magnetostrictive position sensor can also be used in much larger hydraulic cylinders.

If a position sensor cannot be integrated into the cylinder, linear potentiometers outside the cylinder can also be used. In this case, the LZW series linear potentiometer is used. The linear sensor performs measurements in 750 mm ranges with accuracy of ±0.05%. What makes it stand out in particular is the fact that it is a passive component (as per EN 60079-11), which means it can also be used in certain potentially explosive atmospheres.

During brake force measurement, the vehicle is set in motion, either using the engine or an external drive, and the brakes are actuated. The brake test stand’s rollers register and measure the brake force exerted on the wheels. The generated brake force is measured relative to the vehicle’s speed in order to assess the performance of the brakes. This process involves recording various parameters such as the brake force distribution, the braking effect on the front and rear axles and the brake pressure.

The brake test stand allows the testers to measure the brake force on each wheel individually and determine whether it meets the legal requirements. It also allows irregularities or defects to be spotted in the brake system, such as uneven brake pressure or failure of individual brakes.

Finally, the results of the brake force measurement are evaluated and incorporated into the test report. If the brake performance meets the necessary standards, the vehicle receives the required approval or inspection sticker. However, if defects are identified, the vehicle owner must perform the appropriate repairs and submit the vehicle for general inspection again in order to repair the defects and guarantee the safety of the vehicle.

It is important to note that the TÜV brake force measurement only represents the brake force at that given moment and cannot guarantee the long-term functionality of the brake system. Therefore, it is recommended that you regularly have your brakes inspected and maintained at a specialist workshop to ensure that they work optimally at all times and thus guarantee maximum safety.

The importance of monitoring a vehicle’s brake force cannot be overstated. Accurate measurements and regular inspections increase road safety and help prevent accidents. It is essential that vehicle owners as well as professionals in the automotive industry recognise the importance of these measures and take appropriate steps to ensure safety on the roads.