#Product Trends

Gas mixer with remote control – new KM100-MEM+ unveiled

When it comes to gas mixers, the company Witt-Gasetechnik is always the first to spring to mind: The market leader is proud to present its truly state-of-the-art mixing systems for up to three gases … the KM100-MEM+. And it can be operated remotely.

This latest device uses electronically actuated valves, a further leap forward in the technology. And it’s not only the gas mixture setting that is extremely precise in comparison to manual setting. The target values can also be reproduced exactly, even after changes in use. The speed is tremendous too. "It usually takes just a second to get the gas mixture flowing", stresses Witt Managing Director Martin Bender, "no matter which target values you set".

TOTAL REMOTE CONTROL

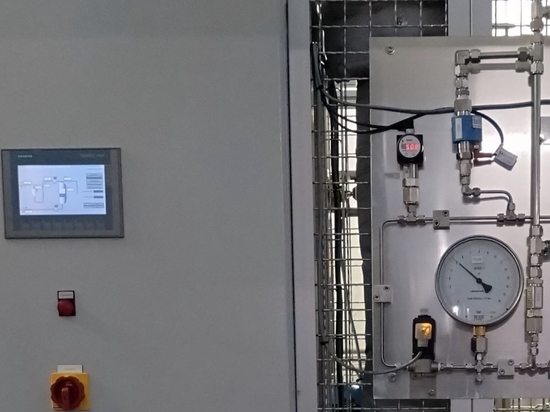

What is more, the latest Witt development provides the option of remote control via processor technology and electronic motor-operated mixing valves. It can be driven via PC, PLC or a machine control system. All parameters can be conveniently called up, set, queried and documented. "That means the mixer can be integrated seamlessly into any of the user's existing infrastructure", states Bender. A new feature of the KM100-MEM+ is an additional touchscreen display. The user can utilise this to check the current settings or change the device parameters.

The gas mixture can generally be set in increments of 0.1 percent and maintained with maximum accuracy. At its maximum 20 bar inlet pressure and 10 bar outlet pressure, the system generates a gas mixture output of up to 544 Nl/min (air equivalent). All technical gases (apart from toxic and corrosive gases) and combinations of combustion gas with air, O2 or N2O can be blended – including mixtures of up to three gases.

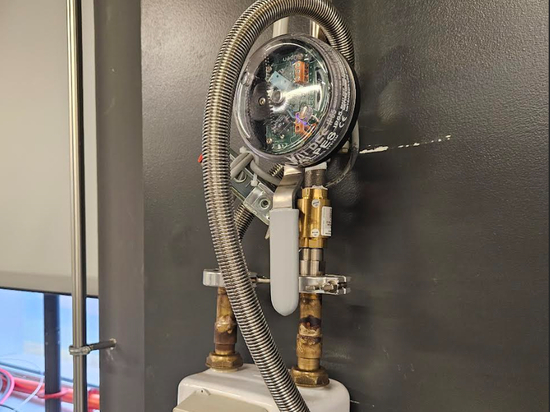

In conjunction with a gas tank, the mixer is suitable for both continuous and batch gas blending. Pressure is accurately controlled using dome pressure regulators which compensate for any fluctuations in the gas supply pressure. The integral gas inlet monitoring system ensures extra safety, by emitting an alarm and/or alarm signal if the pressure is too low. The device can be combined with other modules, such as on-line analysers.

Witt has enclosed its product in a splash-proof stainless steel housing with compact dimensions of only 330 x 485 x 445 mm (HxWxD) and weighing a mere 22 kg. The new mixer is available now. Further information is available at www.wittgas.com.