#Product Trends

Ceramic Metallization Process

Ceramic Metallization Process

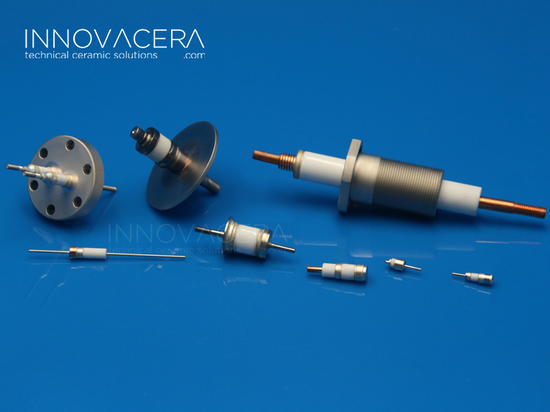

XIAMEN INNOVACERA is a leading suppliers which making metallized ceramics. It is using in brazed solutions.

Metallization applies a thin metallic coating to an area of ceramic parts. Innovacera’s metallized ceramics have a superior brazing characteristics. The thin metallic coating includes molybdenum managanese (Mo/Mn) and tungsten (W). After metallic coating, they will be plating by nickel, gold, silver and so on.

INNOVACERA Ceramic Production Process

The plating method is electroplating. Depend on the ceramic size and the position of metallized, it will decide to barrel or hang plating.

The Mo/Mn thickness is 10-50um, nickel plating is 2-10um. It is flexible. We can do according to your request.

As experts in different applications, Innovacera is available to do metallizing on plate, rod, tube and complex ceramic bodies.

The material for metallization is available for :

Aluminum Oxide

Beryllium Oxide

The benefits of the material:

Low temperature firing

Fast speed process

Uniform coating,thickness and density

Applications for metallization products:

Vacuum Interrupter Ceramic Tube

Feedthroughs

Isolator Flanges

Gas Discharge

Electron Tube

X-Ray Tube

Medical Devices

Vacuum Electronic Devices