#Product Trends

New Star In The Field Of Bulletproof Armor – Boron Carbide Ceramics

New Star In The Field Of Bulletproof Armor – Boron Carbide Ceramics

Boron carbide is one of the hardest ceramic materials, falling just short of diamond and cubic boron nitride. Because of its low density (∼2520 kg/m3), it has become the material of choice for body armor systems.

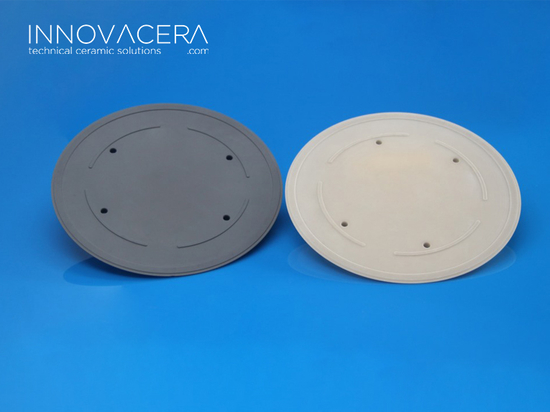

We found that both silicon carbide and boron carbide ceramics have the characteristics of low density. The density of common alumina ceramics is about 3.5g/cm-3, while the densities of silicon carbide and boron carbide are only 3.2g/cm-3 and 2.5g/cm-3 respectively. It can be seen that under the trend of lightweight mobile armor, silicon carbide and boron carbide materials have inherent advantages.

In terms of elastic modulus, the elastic modulus of alumina ceramics is about 350GPa, while the elastic modulus of silicon carbide and boron carbide materials is about 400GPa. It can be seen that the three main armor ceramic materials all have the characteristics of high elastic modulus.

In terms of hardness, boron carbide>silicon carbide>alumina. It is worth mentioning that tungsten carbide is the key material for the production of cemented carbide. Compared with silicon carbide, the hardness of silicon carbide is twice that of tungsten carbide, the density is 1/5 of tungsten carbide, and the strength is maintained at 1400°C.

In terms of wear resistance, boron carbide>silicon carbide>alumina. Data measured by the Institute of Powder Metallurgy of Central South University show that the wear resistance of alumina ceramics is equivalent to 266 times that of manganese steel and 171.5 times that of high-chromium cast iron. It can be seen that the high hardness and high wear resistance of ceramic materials are much higher than wear-resistant steel and stainless steel.

In terms of other properties, boron carbide is unique in high-temperature thermal stability. Compared with alumina, its thermal expansion coefficient is less than 1/2. At 500°C, its thermal conductivity is one order of magnitude higher, and its thermal shock resistance is nearly 20 times higher. But their common problems are low fracture toughness and high brittleness. Therefore, the strengthening and toughening of bulletproof ceramics has always been a hot research direction. Strengthening methods mainly include multi-element ceramic system composite, functionally graded ceramics, layered structure design, etc., Its fracture toughness is poor, the tensile strength is low, and brittle fracture is prone to occur. The ceramic composite target plate must be bonded by the ceramic panel and the composite backplate to overcome the failure of the ceramic due to the tensile stress. This kind of composite target plate is usually made by bonding small pieces of ceramic panels and composite material backing plates, which can also prevent the whole ceramic panel from breaking. When the projectile invades, only a single piece of armor will be crushed.

In addition, the current prices of silicon carbide and boron carbide materials are still relatively high, and the price of boron carbide even reaches 700-800 yuan per kilogram, which is nearly 10 times that of alumina materials. However, with the development of lightweight and high-efficiency armor systems, the superiority of bulletproof ceramics has become more prominent. As the Gemini of bulletproof armor materials, silicon carbide and boron carbide materials, it is believed that there is still much room for improvement.