#Product Trends

Ceramic substrate is the main component of semiconductor devices

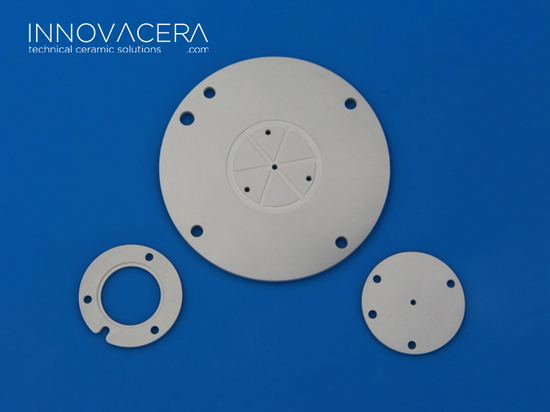

Ceramic substrate

Semiconductor devices are widely used in wind power generation, solar photovoltaic power generation, electric vehicles, LED lighting, and other fields.

Semiconductor packaging materials are substrates that carry electronic components and their interconnections and have good electrical insulation.

The advantages of ceramic substrates include:

Good insulation and resistance to electrical breakdown;

High thermal conductivity: it affects the operating conditions and service life of semiconductors, and the uneven temperature field distribution caused by poor heat dissipation will also greatly increase the noise of electronic devices;

The thermal expansion coefficient is matched with other materials used in the packaging;

Good high-frequency characteristics: low dielectric constant and loss;

Smooth surface and uniform thickness: It is convenient to print the circuit on the surface of the substrate and ensure that the thickness of the printed circuit is uniform.

Development status of ceramic substrate materials for semiconductor devices

1. BeO Ceramic Substrate

Among the beryllium oxide materials, it is a rare ceramic material with high resistance and high thermal conductivity among oxides. Its room temperature thermal conductivity can reach 250W/(m.k), which is equivalent to the thermal conductivity of metals.

2. Aluminum Oxide Ceramic Substrate

Aluminum oxide ceramics is currently the most mature ceramic substrate material for production and processing technology.

The aluminum oxide ceramic substrate has the advantages of low dielectric loss, the little relationship between electrical properties and temperature, high mechanical strength, and good chemical stability.

3. Aluminum Nitride Ceramic Substrate (the best one at present)

AIN ceramic is one of the few non-metallic materials with high thermal conductivity. Its thermal conductivity is more than 5 times that of the aluminum oxide ceramic substrate, which can reach more than 170W/|(m.k).

In addition, the thermal expansion coefficient of AIN is (3.8~4.4) multiplied by 10-6/℃, which matches well with the thermal expansion coefficient of semiconductor chip materials such as SI and silicon carbide.

At present, AIN ceramic circuit board substrates are mainly used in high-end industries.