#Product Trends

Boron Nitride for Molten Glasses Application

Boron Nitride for Molten Glasses Application

Boron nitride, also known as white graphite, has a structure similar to that of graphite. It has good electrical insulation, thermal conductivity, excellent thermal shock resistance and Chemical stability.

BN-sintered parts are generally produced by hot-pressing sintering. The densification mechanism can be described as vitreous sintering. Small amounts of boron oxide (B2O3) function as the liquid phase during sintering and as a binder for the BN platelets. In contrast to some other non-oxide ceramics, there is no solution and precipitation process known for the sintering of BN.

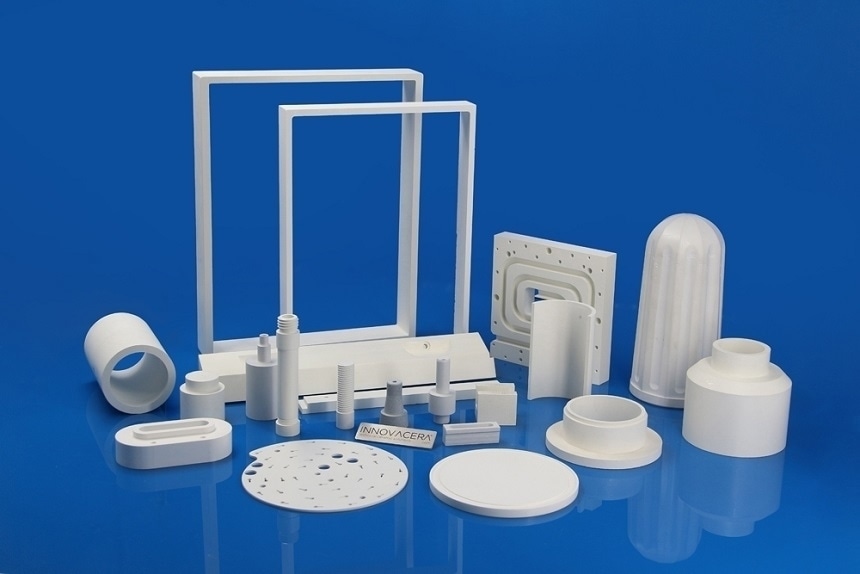

Boron Nitride for the application of glass:

1.Glass Melting – BN crucible

2.Glass Spinning – BN mould (Similar as nozzle. Glass go through it and turn to a

wire)

3.Glass Forming – BN plate

Why Boron Nitride can be used for glass melting?

Boron Nitride ceramic is with good self-lubrication. So glass won’t be stick to Boron Nitride. Also, Boron Nitride is without corrosion during workin.

Hexagonal boron nitride, either in its pure form or as a composite, is an extremely suitable material for special applications at high temperatures. Parts for high-temperature furnaces, crucibles for molten glasses and metals, side dams for thin-strip casting and evaporation boats for aluminium are the most common applications.