#Product Trends

Why is Machining Aluminum Nitride Ceramics Challenging?

Why is Machining Aluminum Nitride Ceramics Challenging?

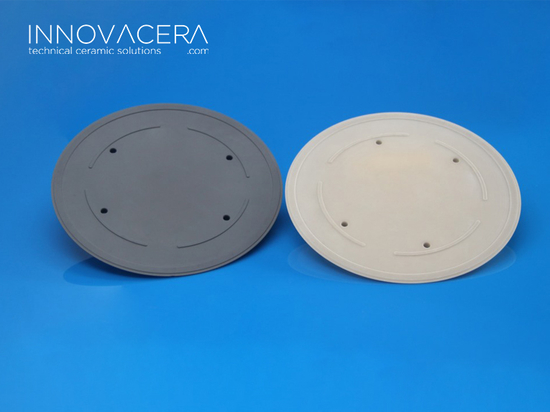

Aluminum nitride ceramics, composed mainly of aluminum nitride, possess remarkable properties such as high thermal conductivity, excellent insulation, and low dielectric constant. The crystal structure of aluminum nitride consists of tetrahedral units forming a covalent-bonded compound, exhibiting a spinel-type structure within the hexagonal crystal system. With a chemical composition of 65.81% aluminum and 34.19% nitrogen, and a density of 3.261g/cm3, aluminum nitride ceramics appear white or gray-white, with single crystals being transparent and colorless. These ceramics boast a sublimation decomposition temperature of 2450°C under standard pressure, making them ideal for high-temperature applications. Additionally, their coefficient of thermal expansion ranges from 4.0 to 6.0 * 10^-6/°C, and their polycrystalline form exhibits a thermal conductivity of up to 260W/(m·K), surpassing that of aluminum oxide by 5-8 times, thus demonstrating excellent resistance to thermal shock up to 2200°C. Furthermore, aluminum nitride showcases resistance to corrosion from molten aluminum and other metals, particularly demonstrating outstanding resistance against molten aluminum corrosion.