#Product Trends

Pyrolytic Boron Nitride/PBN Plate Heater

PBN Plate Heater

CVD is a versatile technology that can allow many different freestanding shapes to be manufactured, as well as coatings on a variety of different substrate materials.

PBN products are well suited for use in Moleculaar Beam Epitaxy(MBE), Metal Organic Chemical Vapour Deposition(MOCVD), Crystal Growth and other applications, where high purity and chemical stability are required. The anisotropic conductivity of PBN improves process performance for crystal growth, whether the growth method is Liquid Encapsulated Czochralski(LEC) or Vertical Gradient Freeze(VGF).

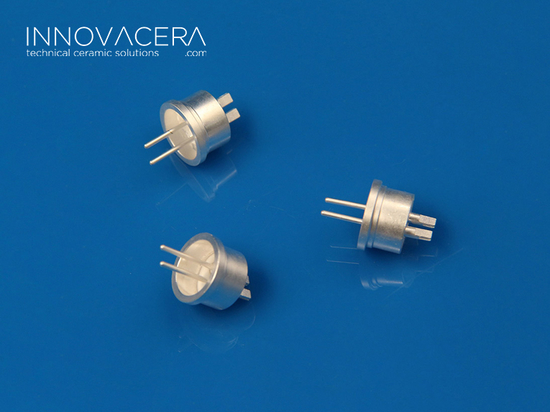

Flat and tubular heater elements can be produced by depositing a conducting layer of Pyrolytic Graphite(PG) onto an insulating substrate of PBN. A track can then be machined in the PG layer which can then be protected by an over-coat layer of PBN. These heaters have a very fast response and a low thermal mass. They are ideally suited for use in Ultra High Vacuum, or corrosive chemical enviroments.

PBN properties, it''s intrinsic purity, superior mechanical strength and thermal stability make it a superb choice for high temperature furnace and electrical components, microwave and semiconductor components, and industry stadardized crucibles for gallium arsenide crystal production.