#Product Trends

Controlling sensorless brushless DC motors using advanced controllers and back-EMF

Sensorless can reduce cost without affecting performance

Increasingly popular everywhere…

Brushless motors are proving increasingly popular, largely due to the additional life (no brushes that can wear) that they offer but also because of some of the more unique properties that they offer. Increasing amounts of Zikodrive customers are coming to us looking to replace existing brushed motors with a low cost brushless option which can match the performance they get from brushed motors. However, many other customers choose brushless because of the inherent performance advantages.

Sensored or sensorless, that is the question…

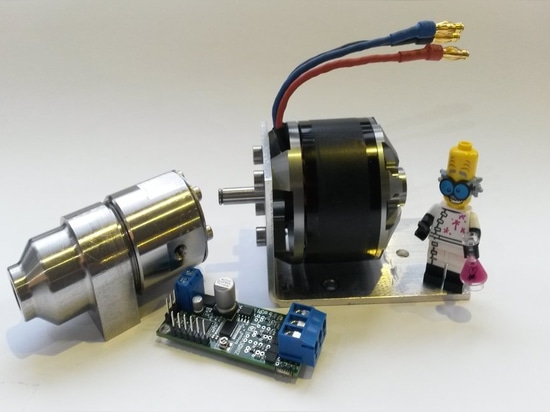

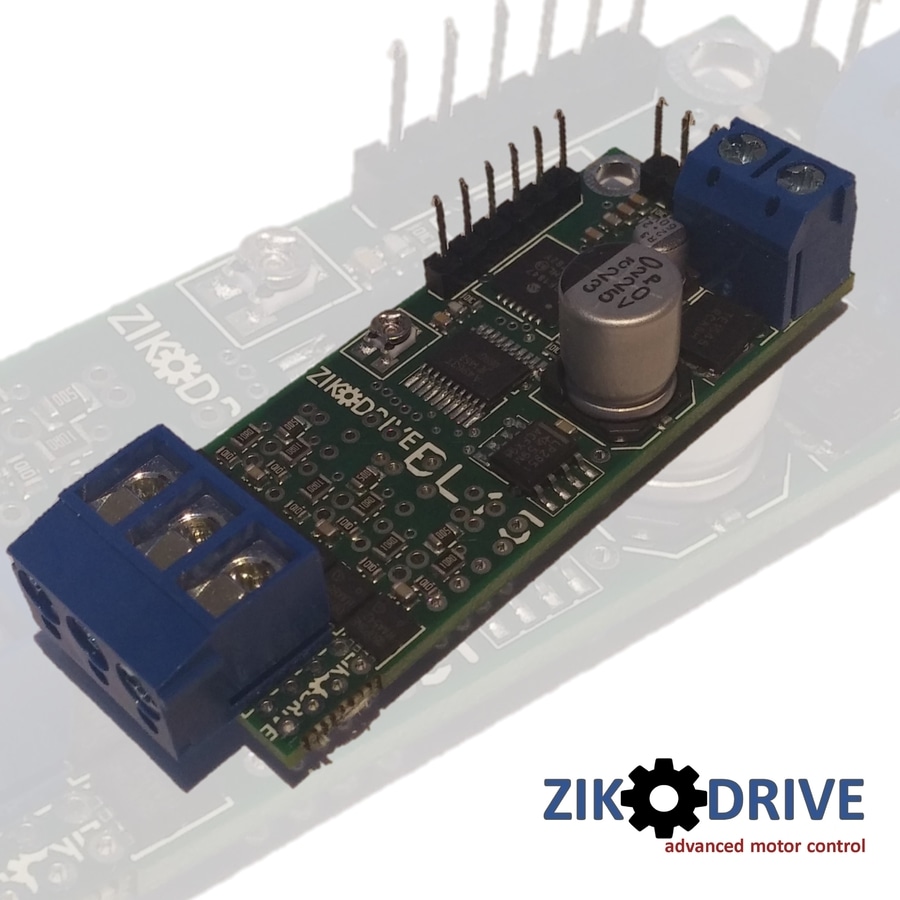

One of the first questions which then comes up is whether to use sensored or sensorless brushless DC motors. Sensored motors are seen as being technically better because the ability to use sensors to detect position enables greater monitoring of speed but also assists with start up as it is possible to detect position quickly. However, the cost of sensored motors is higher and setup can be more complex, particularly for those customers who are looking to replace very simple brushed DC packages. For these applications, intelligent controllers such as the ZDBL5 which can use back-EMF to measure and maintain constant speed offer a lower cost and simpler option.

Why use back-EMF?

The importance of using back-EMF in sensorless applications is huge as it enables a direct measurement of motor performance without the need for additional sensors because the EMF generated is always proportional to the velocity of the rotor. By measuring the back-EMF, advanced BLDC controllers such as the Zikodrive ZDBL10 or ZDBL15 can measure exact motor performance and make fine adjustments as required to ensure a constant speed or torque. On a recent test conducted by Graham Fick, (Technical Director of Zikodrive Motor Controllers) it was found that such technology enabled a centrifugal pump to achieve less than 1% dosing error on 50ml doses using no flow-meters or other measuring technology.

Conclusion

Ultimately the choice of motor for an application depends hugely on the specific needs of that application, be they cost, technical performance, lifespan or other factors. However, the accuracy available using sensorless brushless DC motors with controllers such as the ZDBL15 makes them a very attractive option for a large number of applications.