#Product Trends

New SPN modular zero-point clamping system from Zimmer Group

Models with multiple features ensure short changeover times – High-end variant satisfies every wish

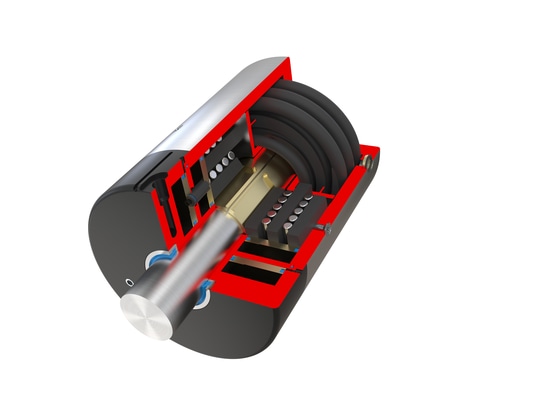

In January 2021, Zimmer Group is presenting its new SPN modular zero-point clamping system, which has an impressive number of features and meets even the highest demands. In addition to the Standard variant, which is reduced to basic functions such as un-locking and the PLUS connection, an Advanced variant can also be selected.

The new SPN Advanced variant is a high-end version that is especially popular in automated production. The tempered stainless steel and thus rust-free zero-point clamping system of the Advanced series offers a range of functions that are unique on the market in this form and composition. Besides the standard PLUS connection – an additional pneumatic connection that helps significantly increase clamping forces – the extremely practical func-tion of the integrated positioning check is especially noteworthy. The positioning check uses a connected flowmeter or Pitot tube to make it possible to check whether the workpiece or clamping pallet is laying flat on the surface of the zero-point clamping system. Like the blowout function of the pin opening and the contact surface cleaning, pneumatic piston position sensing is also integrated into SPN Advanced as standard. The SPN Advanced zero-point clamping system offers the user maximum flexibility with no less than two connection options – one via spot facing on the flange surface and another via a hose system on the base of the system. Safety is also a key issue for the SPN Advanced. In addition to the blow-out function, installed as standard, an optional automatic sealing cap also provides optimal protection against the ingress of foreign particles.

Maximum forces with the highest repeatability

Both zero-point clamping systems (SPN Standard and SPN Advanced) are capable of absorbing maximum forces with the highest repeatability. This is achieved through a sophisticated clamping principle that uses clamping segments for positive locking. In comparison to conventional systems where balls are in point contact, clamping segments adapted to the clamping contour establish the surface contact between the clamping system and pin. This gives the systems a very high stiffness.

Extensive accessories

The product range is expanded by clamping plates with pre-integrated zero-point clamping systems. They have Standard SPN zero-point clamping systems as standard and also have the option to be equipped with SPN Advanced if the customer requires the sensing option for its application. The accessories here range from clamping plates with two zero-point clamping systems to clamping plates with six zero-point clamping systems. This ensures that all real-world applications are covered. An automatic seal that reliably protects the pin opening as well as clamping pins are also available as options. The clamping pins can be integrated directly into the workpiece using the zero-point clamping system to clamp the workpiece with precision, repeatability and cost efficiency. This approach makes it possible to perform complete five-side machining in one workpiece clamping setup. The various clamping pins here ensure the desired precision clamping behavior in different three-dimensional axes. The centering pin defines the reference point for the workpiece and provides precision in the X, Y and Z direction. While the sword pin provides precision in the X, or Y and Z direction, the clamping pin clamps only in the Z direction. What's more, a separate locking pin, which locks the pin opening if not in use for optimal protection, is already included in the scope of delivery.