#Industry News

Digitalization of sensors or how intelligent connectors are changing sensor and measurement technology

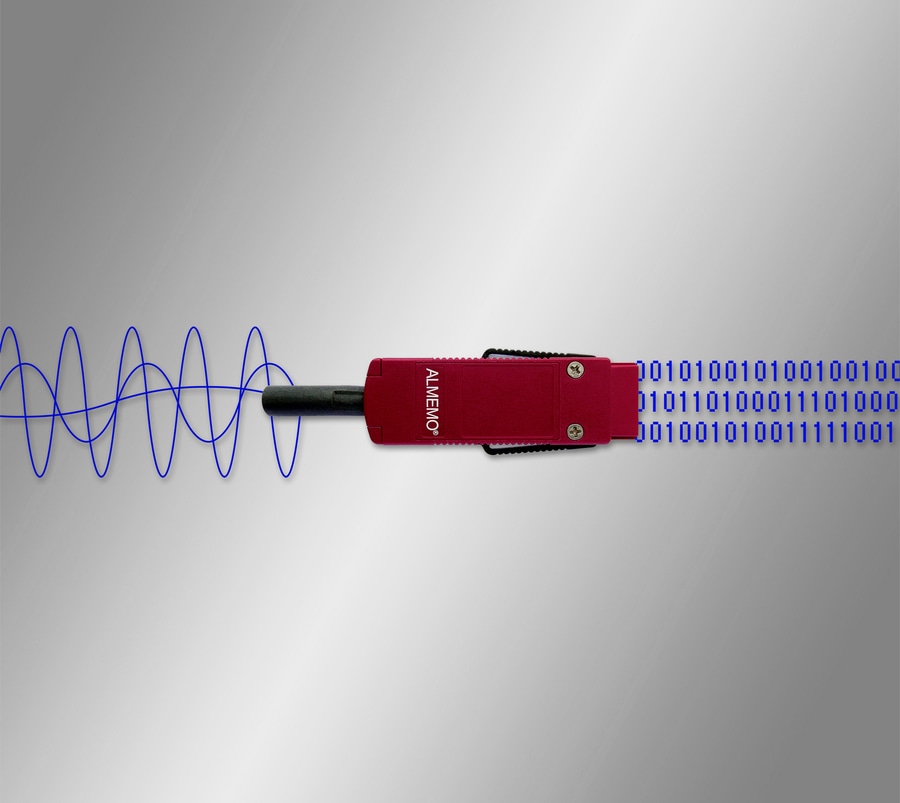

The conversion of analog, physical, chemical or electrical values into digital formats is best started in the connector plug. This gives the entire measurement chain the greatest flexibility.

In many areas of automation, the process industry or in research and development tasks, measurement technology today is faced with an increase in diverse and complex measurement tasks. It is becoming increasingly difficult to interpret and evaluate the growing volumes of data. In addition, quality standards and the need for certifications and calibrations are increasing in almost all areas. Other factors include costs and time. Analog sensor technology is reaching its limits here. Digitization of the measured values to be recorded is essential for integrating the required measured values into data processing systems. The conversion of analog, physical, chemical or electrical values into digital formats is best started in the connector plug. This gives the entire measurement chain the greatest flexibility.

Compact measurement technology for all applications

Back in the early 1990s and before, the family-owned company AHLBORN recognized the value of flexible connection options by separating the electronics between the measuring device and the sensor. The patented ALMEMO® connector system was created by integrating an EEPROM/memory module into the connector plug and programmed sensor recognition. The possibilities for solutions to measurement tasks increased many times over. To this day, ALMEMO® measurement technology means that a single measuring device or data logger can be used to measure almost any physical, electrical or chemical variable, and only the sensor needs to be replaced. The sensor is automatically recognized by the measuring device via preconfigured or freely programmable plugs when it is plugged in. After changing the sensors, no adjustment is necessary on the device and the measured value is displayed immediately. The technology can be used for simple measurement tasks through to autonomous measurement data acquisition with an individual measurement setup. In addition to standard measurement tasks, complex, customer-specific special solutions can also be implemented.

The intelligence is in the connector plug

The further development of the intelligent connector plug ultimately led to digital solutions in the field of sensor technology and has been realized at AHLBORN for almost 10 years. More powerful microprocessors have made it possible to create completely self-sufficient digital sensors that function like a measuring device themselves. The intelligence of the digital sensors is located in the connector plug. In addition to the additional flexibility of a digital sensor, individual sensor parameters such as linearization, scaling, attenuation, averaging, measuring rate or longer comments can also be stored in the intelligent ALMEMO® D7 and D6 connectors, for example for clear assignment of the sensors to the measuring stations. Of particular interest is the possibility of digitizing sensors from completely different manufacturers via the intelligent connector and connecting them to ALMEMO® measuring systems.

Calibration, cost-effective and fast

The digitization of sensors makes it possible to consider the measuring device and sensor separately during a traceable initial calibration or recalibration. The device itself no longer needs to be taken into account during calibration. Each digital sensor with an ALMEMO® D7 or D6 connector forms a self-contained, calibratable measuring chain. This means that the sensors can be calibrated independently of the measuring system, saving time and money, and the measuring device no longer represents an uncertainty factor. To avoid possible process downtimes or high installation costs, only one additional sensor is required as a replacement. In addition, several calibrations can be carried out simultaneously on different sensors of a system, which leads to a considerable reduction in the overall calibration time. In AHLBORN's in-house, accredited calibration laboratory, the sensor deviation is determined at each calibration point during the calibration of temperature and pressure sensors and, at the customer's request, stored as a correction value in the intelligent connector for each calibration point. The measured values for the multi-point adjusted sensor are then entered in the calibration certificate. The reported sensor deviations are close to zero. Measurements within the calibrated interval can then be carried out with smaller uncertainties.

Overcoming boundaries in application areas, from individual devices to measuring systems

ALMEMO® digital technology makes it possible to connect devices from different manufacturers such as scales, centrifuges, particle counters or numerous sensors with analog or digital interfaces and other communication protocols to the ALMEMO® data logger. Once adapted, all data and sensor parameters are automatically detected, immediately visualized and recorded centrally or decentrally simply by plugging the connector into the measuring device. Measuring devices that were previously difficult to implement become highly flexible everyday measuring aids, without the need for programming, parameter changes or software adjustment.

The advantages are obvious

Thanks to digital signal transmission, any cable length is possible on the digital sensor. Electromagnetic interference is eliminated and measurement signals can be transmitted over long distances without interference. Digital sensors can be replaced without loss of calibration data. High measuring speed, high precision and resolution as well as stable measured values are the hallmarks of digital sensors.

The separation of an electronic conversion of analog to digital signals from the sensor and the accommodation of the digital technology in the connector opens up a multitude of further metrological advantages. For example, a digital ALMEMO® D7 or D6 connector offers space for 10 measurement and calculation channels. The display ranges in the measuring device can be extended to 200,000 digits when using this new type of connector. The device-independent display of the sensor parameters and the configuration of the sensor are carried out via the patented sensor menu. As it is now possible to connect third-party sensors from all manufacturers, the existing measurement technology can be expanded as required.