#Product Trends

Mini-PLC in use in refrigeration technology

Snowflakes in perfection

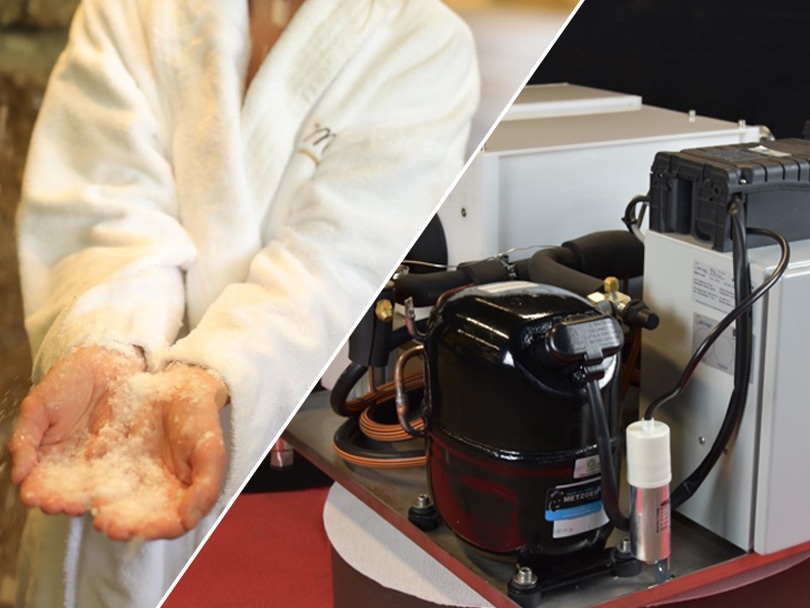

Snow at the touch of a button - every child's dream comes true with the snow shower cabins or snow shower cubicles from Metzger MSK. The company supplies its snow machines from the Black Forest, Germany, all over the world. Inside the machines, a programmable relay from akYtec ensures perfect operation.

The snow is gently falling in midsummer. It is +40 °C outdoors, yet the snowflakes from MSK’s snow shower cabins of the SLX series provide cooling indoors. Air conditioning systems, ice water pools and snow machines – Metzger MSK is dedicated to year-round snowmaking. The company from Hofstetten near Freiburg has been selling machines for the production of snow, ice, and cold since 2007. Bertin Metzger, the managing director and owner, and his team deliver snow out of the Black Forest to all corners of the globe - from Europe through Russia to Canada, in the United Arab Emirates and the Maldives.

"The anomaly of water has always fascinated me," says the expert in refrigeration technology. Water has that unique property that distinguishes it from other liquids: it has the smallest volume and the highest density at 4 °C. Metzger turned his passion into a profession at some point and began to produce snow and ice at temperatures above freezing. Initially, his company produced crushed ice for bakeries and butchers. With the first machine in the event area, a new business field opened up, which has meanwhile become the main field of activity. Metzger has even patented his method of producing technical snow.

Functional and compact

The PR200 Programmable Relay from akYtec GmbH ensures perfect control of the production of ice crystals in many MSK machines. Since this mini PLC combines and compactness with its many connection options, it is used as an alternative to the more expensive PLC control. "Here we have everything we need on board," says the entrepreneur Metzger, "from analog/digital inputs via RS485 interfaces through to the program memory".

The PR200 takes over the complete sequence control of snow and ice production. Different types of inputs are engaged: 0-10 V, 0-4000 ohm, and 4-20mA. Sensors detect refrigerant pressure in the range of -0.5 to +40 bar and various temperatures. The digital inputs are connected to float switches, Hall effect sensors, and pushbuttons. The actuators connected to the outputs ensure respective impacts on snowmaking – coordination of the water supply, regulation of the valves, running performance of the motors and refrigeration units which keep the temperature constant. The PR200 can be integrated into a Modbus system over the RS485 interface. In the case of Metzger, the machines are interconnected via this interface to a touch screen, which facilitates the operation and monitoring of various snow machines.

No dust particles needed

Technical snowmaking at Metzger is carried out hygienically and without the use of chemical or bacteriological additives. In natural conditions, a dust particle is needed to form a snowflake. Crystals attach themselves to the dust grain, and a flake grows from it over time. Conventional machine snow production aims to imitate this natural process. A snow cannon usually requires cold temperatures of 0 °C or less for nucleation, i.e. the transition from water to ice. The faint haze then gets frozen with compressed air and distributed with a fan or the like. In some places, so-called snow influencers in the form of proteins are used to increase the nucleation temperature of the water, and thus the availability of artificial snow.

Metzger, however, operates his snow machines and snow shower cabins on flake ice obtained by water dispensation onto a rotating ice-cold roller where it then freezes. "The newly formed ice is scraped off with a knife as if we were scraping frost from the windshield of a car," explains Metzger. "This way, we obtain the smallest crystals that can be piled up and look like natural snow. The significant advantage is that this snow production is independent of outside temperatures and does not require any chemicals. "We naturally optimize the cold potential and thus cause the snow to melt more slowly.

Innovation pioneer in snow shower cabins

Metzger has installed the PR200 from akYtec since 2016; and since then, this device has been used in a wide variety of refrigeration products for applications in events, winter sports, research, industry, or in the wellness and spa sector. With its MSK SLX series, Metzger is a pioneer and innovator who offers compact and service-friendly products. The USPs that Metzger appreciates about akYtec products: "The support is excellent; the delivery times are short." The compactness of the PR200 convinced him one time. Programming is carried out using the akYtec ALP software, which is available free of charge. The control loops can be created in the function block language (IEC 61131-3). A mini USB port is available for transferring the program to the PR200.

It was decisive for Metzger to have excellent functionality in a wide temperature range, whereas the PR200 even exceeds these requirements by far and works reliably at -20°C as well as +55°C. The PR200 mini PLC is also protected against mechanical vibrations. Twelve inputs and ten outputs can be extended with additional modules.

Snowmaking is a theme that always shows Metzger a new face. The snow expert never tires of recognizing new needs and, above all, of implementing innovative ideas in the spa sector and the leisure sector. "New products are always wanted," remarks Bertin Metzger. The latest highlight is an ice-water shower in the style of the popular Ice Bucket Challenge, which discharges cold water of three to four degrees at the touch of a button, which is especially popular after sauna courses.