#Product Trends

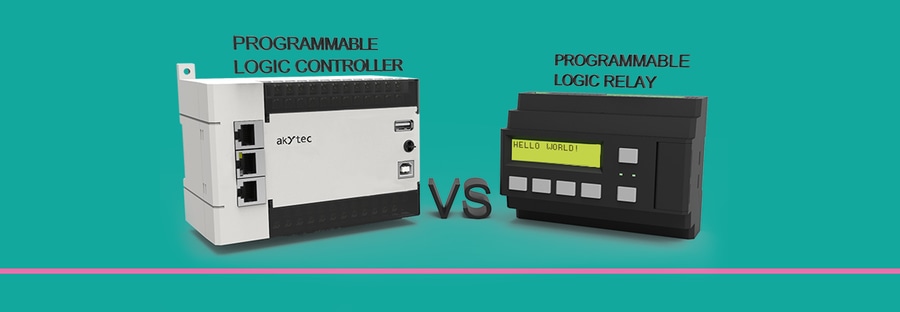

PLC vs Programmable Logic Relay

Programmable Logic Controller (PLC) is the most significant component in the industrial automation sector. In terms of applicability, PLC is a special purpose small computer primarily used in industries or any other field related to control system.

Modern PLC is a device of high performance which is specially designed to operate in harsh conditions and protected from high levels of electrostatic discharge (ESD), large transient voltage swings, electromagnetic interferences (EMI), etc. It usually supports many interfaces (RS485, Ethernet, CAN, LVDC, etc.) and communication protocols (Modbus, Profibus, CANopen, EtherCAT, DeviceNet, EtherNet I/P, etc.). PLCs are no longer restricted to the solitary ladder programming language. Rather they can be programmed with any of 5 languages – Function Block Diagram (FBD), Instruction List (IL), Ladder Diagram (LD), Sequential Flow Chart (SFC) and Structured Text (ST) – which are compatible with international standard IEC 61131 for programmable logic controllers. Some PLC’s programming environments allow the developer to flexibly mix and match different programming languages in a single CPU, for example, of SPK207 Control Panel from akYtec with CODESYS V3.5. Besides its support of many data types, libraries, visualisation elements, own non-standard protocols can with CODESYS also be implemented and the application programs can be written using Object-oriented programming (OOP) paradigm. Due to such extensive software capabilities and PLC’s capacity of memory, complex and large projects of process control for almost any industrial purposes can be done using PLC.

But sometimes such a high performance is not needed and efficiency has higher priority. Therefore many manufacturers solve this matter releasing simplified PLCs, called programmable logic relay (PLR), compact PLC, smart relay, or other name implying small controllers. These devices are usually not modular and feature less memory capacity, fewer interfaces/protocols and less I/O points, what makes them more compact. These simplifications result in efficiency in terms of price. They, at the minimum, are generally two times less expensive than PLCs. Another advantage of PLRs is substantial savings in time of their programming because they usually come with intuitive and easy-to-use programming environment. This significantly reduces time of creating the user program without involving high-paid programming developers.

AkYtec doesn’t stand aside and also offers some devices that solve this operational challenge – programmable relays of PR1XX series and a more sophisticated device – PR200. They all are equipped with Real-Time-Clock and can be expanded with I/O-Modules. With user-friendly and free of charge programming tool akYtec ALP, you can create simple and effective solutions for industrial need, such as pump control, lighting, HVAC, home automation and other simple automation tasks without any complicated and expensive programmable logic controllers.

- See more at: https://akytec.de/en/blog/plcvsplr#sthash.exP8vFMW.dpuf