#Product Trends

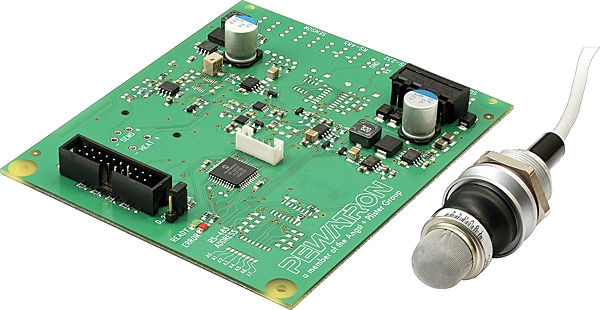

Zirconia based oxygen OEM sensor module: FCX-MC25-CH measures oxygen concentration extremely fast and precisely

Measures changes in oxygen concentration in 2-5 seconds

Typical applications requiring a fast response time by the sensor include those where only small sample extracts are available for analysis or where a large number of samples are to be tested/analysed. For both applications, knowledge about the response time (T90) is important to be able to make correct assessments of the process and product quality.

Selective laser melting (SLM) is a good example of an application where the response time of the oxygen sensor is important when measuring changes in oxygen concentration. When using metal powder to build a 3D model via laser sintering, minor alterations in oxygen concentration can cause major structural changes to the model due to unwanted selective oxidation of the metal layers. It is important to monitor the oxygen changes in the chamber and to couple these changes to counteractions, e.g. by increasing the vacuum pump speed. It is important for the steel metal system – and highly important for metal systems featuring aluminium, titanium or nickel – to be able to react to sudden changes in oxygen concentration during the process.

The oxygen sensor is configured in a flow configuration with connectors for hosing. The sensor is encapsulated in a pressure-proof aluminium flow housing, enabling oxygen concentrations to be analysed from small sample extracts. The output oxygen concentration is highly linear, with a degree of accuracy greater than +/-0.5% vol. O2. It also has a response time of less than 5 seconds for gas concentration changes. Concentration ranges are from 0 to 25% vol. O2.