#Industry News

FCX-OHS HUMIDITY SENSOR

FOR PROCESS CONTROL IN LARGE BAKERIES

Yield management in industrial processes rely increasingly on sensors that can monitor the process. By monitoring the process, the optimum working point of a process can be defined and product yields can be maximized. An industrial bakery with a high throughput is a perfect example of an industrial application, where a closed loop control of the full baking process can be used to minimize waste of the bakery products.

An industrial bakery oven is a complex machinery with very thick insulated walls, heaters and various baking zones for the baking process. The dough is normally steamed at the entrance of a very long and wide baking zone, and the steaming process together with the subsequent baking process is essential for the appearance and the taste of the final product. By installing humidity sensors along the baking path in the oven, the whole process is not only monitored, but can also be controlled and parameters can be optimized during the production run itself. This is named the Bakery 4.0 concept, in which sensors working in a network between different parts of the oven and between different ovens are used for process optimization.

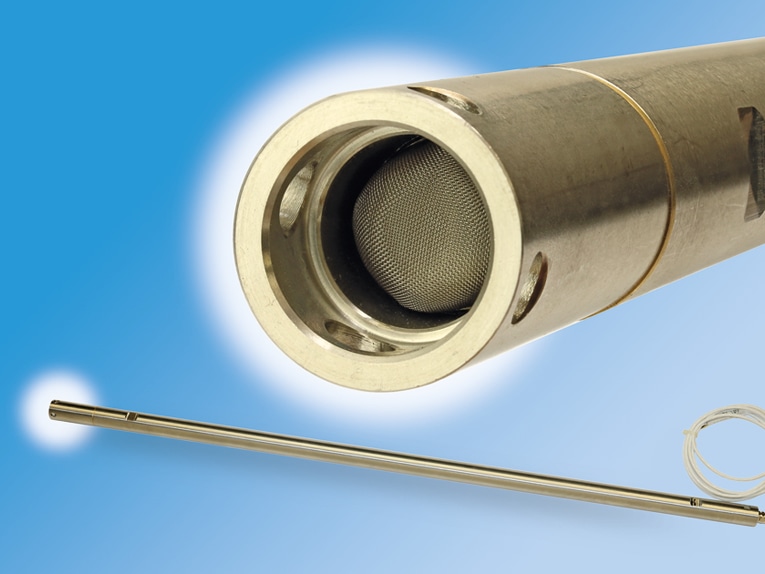

Pewatron is selling humidity sensors for monitoring the baking process in industrial bakeries. The FCX-OHS humidity sensor product can withstand 350°C and is extremely robust in design. It measures the humidity in the oven atmosphere relative to the oxygen content, and is thus perfectly suited as a process-monitoring sensor for closed loop control operation.

The heart of the FCX-OHS sensor is zirconia ceramic disc that provides a constant current of 20 mA from an atmosphere without any humidity present. If the atmosphere is saturated with water (100% humidity), the current changes to 4 mA. In the current output range from 4 to 20 mA, the atmosphere holds a certain amount of water, and the relationship between current and amount of water in the atmosphere is inversely linear.

The sensor head of the FCX-OHS sensor can easily be operated up to 350°C, but the electronics, cabling and packaging of the sensor head remain a challenging task when the requirements of temperature operation exceeds 200°C. The FCX-OHS sensor is manufactured using materials for high temperature operation. The length of the FCX-OHS sensor can be adjusted between 40 and 2500 mm depending on the position of the sensor in the process and the thickness of the oven insulation. The sensor signal is fed to the 4-20 mA transmitter box via special high temperature cables and connectors. Very important for the accuracy and operation is the calibration routine, which is done exactly at the temperature of operation. The accuracy is checked in a broad range of +/-50°C away from the operating temperature. Every FCX-OHS sensor is delivered with a certificate of conformance and a certificate of analysis.

The FCX-OHS sensor was developed for process monitoring in industrial bakeries, but the concept can be used for many other drying and wetting process applications at high temperatures. The sensor also works in certain combustible atmospheres, but the accuracy may be somewhat compromised.