#Product Trends

MEMS CATALYTIC & THERMAL CONDUCTIVITY SENSORS FOR DETECTION OF FLAMMABLE GASES

When operating the fire triangle, several strategies are taken in order to prevent devices & systems catching fire upon a malfunction. One very popular and legislation driven strategy is to measure the concentration of the flammable gas.

Traditionally the concentration of flammable gases are measured using catalytic sensors and/or thermal conductivity sensors. These sensors normally suffer from high power consumption and a high degree of craftsmanship upon manufacturing of the sensors, meaning that certain high volume applications are difficult to serve. In this newsletter, we present new MEMS based catalytic and thermal conductivity sensors that both operate under very low power and are both manufacturable in very high quantities.

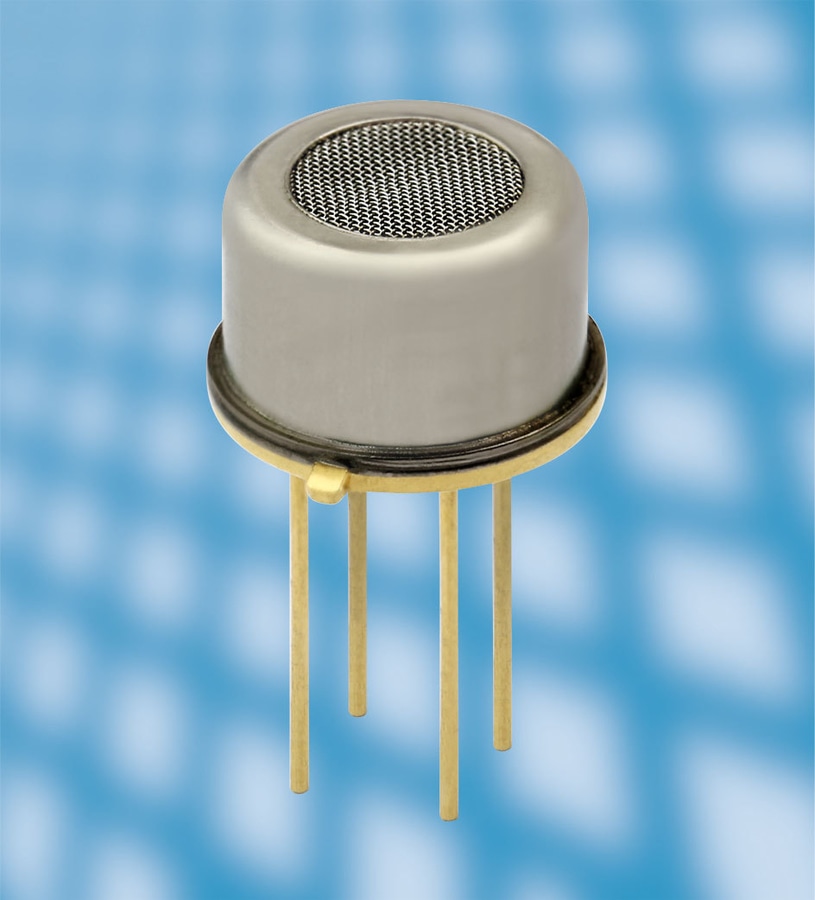

The new MP-7217 MEMS catalytic gas sensor is a low power consumption sensor – designed for use in battery-operated devices and optimized for a methane, propane or butane response up to the LEL limit for these gases. The gas-sensing element is a two-chip system with one sensing and one compensating catalytic structure each deposited on a heater on a silicon chip. By the use of MEMS technologies, the power required to heat up the sensing and compensating layers is only 120mW in average, which is unsurpassed by any other technology for catalytic gas sensing. The packaged sensor element MP-7217 has a small footprint (Ø14.4x6.7mm), but can alternatively be built into a standard catalytic bead housing (VQ548MP; Ø20x20.9mm) for full compatibility with standard catalytic bead products (VQ548 series).

The new PTC-01P MEMS thermal conductivity sensor is a silicon sensor die in a TO housing. The MEMS sensor die consists of two platinum thin-film resistors – one of which is located on a thin membrane etched into the silicon. The measurement principle of the PTC-01P sensor is a differential measurement of thermal conductivity relative to air. CO2 or other gases with a sufficiently large difference in thermal conductivity compared to air will change the measuring value of a measurement resistor more than that of a reference resistor. Using constant current heating of the membrane, the difference in temperature between the reference and the measurement resistor correlates with the thermal conductivity of the surrounding gas. The reference resistor is also used to compensate the dependence of the thermal conductivity on the absolute temperature.

One key feature of the PTC-01P is the ability to operate in a very wide temperature range from -40°C to +85°C, whereas best performing NDIR gas sensors can only operate in a range from -20°C to +65°C. Another key feature is the very fast response time of the sensor, which is only limited to changes in the measurement resistor. The PTC-01P sensor has a very low power consumption (5 mW) and is superior to most NDIR based gas sensors in this respect too. The achievable resolution of the PTC-01P sensor is highly dependent on the conditioning electronics and the ability to measure very small differences between the reference resistor and the measurement resistor.

Another unique feature of the MEMS membrane based gas sensor in comparison with a standard catalytic & thermal conductivity sensors, is the high resistance towards mechanical shocks, because of the use of MEMS technologies.