#Product Trends

Unveiling the Dynamics of Cryogenic Ball Valves

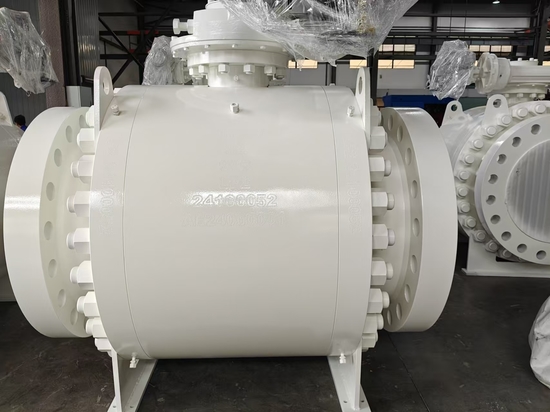

ball valves

In the ever-evolving landscape of industrial valves, cryogenic ball valves have emerged as critical components, especially in applications where extreme cold conditions prevail. These valves, designed to operate in cryogenic environments, play a pivotal role in industries such as liquefied natural gas (LNG), petrochemicals, aerospace, and medical gases. In this article, we delve into the intricacies of cryogenic ball valves, shedding light on their design, applications, and the noteworthy contributions of Athena Engineering, an experienced China-based manufacturer certified with ISO 9001 and fire safety credentials.

Cryogenic ball valves share similarities with their conventional counterparts but are equipped with design enhancements to withstand the challenges of cryogenic service. These features include extended bonnets to shield the stem and packing from extreme temperatures, materials selected for low-temperature applications, and specialized sealing mechanisms to ensure tight shut-off even in sub-zero conditions. Design innovations for cryogenic environments:

A. Extended Bonnets: One of the hallmark features of cryogenic ball valves is the incorporation of extended bonnets. These elongated structures serve a crucial role in safeguarding the valve's internal components, such as the stem and packing, from the intense cold. By minimizing heat transfer to these critical elements, extended bonnets ensure the valve's continued functionality in sub-zero conditions.

B. Materials Tailored for Low Temperatures: Cryogenic ball valves are crafted from materials specifically chosen for their ability to withstand extreme cold. Common materials include stainless steels, nickel alloys, and other exotic materials that maintain their structural integrity and mechanical properties even at cryogenic temperatures. This careful selection prevents brittleness and ensures the valves can operate seamlessly in low-temperature applications.

C. Specialized Sealing Mechanisms: Achieving a reliable seal is paramount in cryogenic applications. Cryogenic ball valves are designed with specialized sealing mechanisms, often incorporating materials like polymeric or elastomeric seals that remain pliable in extremely low temperatures. This ensures a tight shut-off, preventing leakage and ensuring the safety and integrity of the systems they regulate.