#Product Trends

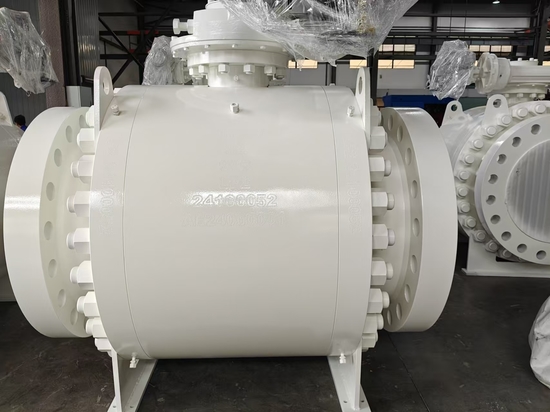

Oxygen Globe Valve

Ensuring safe and efficient oxygen flow in industrial applications

What is oxygen valve?

An oxygen globe valve is a specialized valve used in oxygen piping systems to control the flow and pressure of oxygen. It is crucial to ensure the safety and stability of industrial processes that rely on oxygen, such as steelmaking, medical applications and chemical industries.

Key features of Athena Engineering S.R.L's oxygen globe valves include

1. High sealing performance: Athena Engineering S.R.L's Oxygen Globe Valves use advanced sealing materials and techniques to maintain excellent sealing performance even under high pressure and high purity oxygen environments. This prevents oxygen leakage and ensures the integrity of the piping system.

2. Corrosion Resistance: The valve body and critical components are made of stainless steel and other corrosion-resistant materials. These materials undergo special treatments, such as pickling and passivation, to further enhance their durability and performance in oxygen-rich environments.

3. Antioxidant properties: Our valves are designed with special antioxidant properties, which allow them to maintain stable performance over extended periods of exposure to oxygen, thereby prolonging their service life.

4.pipeline and ensure system safety.

Safety features: Safety is the first priority in our valve design. Athena Engineering S.R.L's Oxygen Globe Valves incorporate anti-static and fire resistant structures. All parts undergo a rigorous degreasing treatment before installation to eliminate unsafe factors in the oxygen

5. Compact design: The compact design of our oxygen globe valves makes them easy to install and maintain. They are also designed for easy operation, whether manual, electric or pneumatic, to improve work efficiency.

Oxygen Globe Valve Applications

Athena Engineering S.R.L's Oxygen Globe Valves are widely used in industries that require high purity and high pressure oxygen, including

- Steel industry: Where oxygen is used as an oxidizing agent in steel smelting processes, requiring high safety and reliability standards for oxygen piping systems.

- Medical fields: Hospitals require a large supply of oxygen for patient treatment, requiring oxygen piping with stringent safety and purity requirements.

- Chemical industry: With numerous gas processing processes in which oxygen serves as an essential raw material and auxiliary agent, reliable oxygen piping systems are critical to production safety.

Oxygen Globe Valve Degreasing Process

Oxygen globe valves play a critical role in controlling the flow of oxygen and ensuring the safe and stable operation of the entire system. However, due to the highly reactive nature of oxygen, a critical step in the manufacture and maintenance of these valves is degreasing and oil prohibitive treatment. This article will discuss the importance of degreasing oxygen valves and the specific process involved.

Importance of Degreasing

Oxygen is a highly oxidizing gas. When it comes into contact with oily substances, especially under high pressure, it can cause violent chemical reactions. These reactions generate large amounts of heat and may even lead to explosions. In addition, oil can affect the sealing performance and operational flexibility of the valve, accelerate component aging and wear, and shorten the life of the valve. Therefore, degreasing and anti-oil treatment of oxygen valves is of great importance. This treatment is designed to thoroughly remove oil and contaminants from the surface of the valve and its components, preventing them from reacting with oxygen. It also ensures the sealing performance of the valve, prevents oxygen leakage, and improves the overall safety and stability of the system.

Degreasing Process

The degreasing process for oxygen valves typically involves several steps: cleaning, degreasing, drying, and inspection.

1. Cleaning: The first step is to clean the valve surface to remove dirt and debris. This ensures a clean surface for the subsequent degreasing step.

2. Degreasing: Degreasing involves the use of specific degreasing agents such as acetone, alcohol, or other inorganic, non-flammable cleaners to thoroughly remove oil from the surface of the components. For metallic materials, solvents such as dichloroethane, trichloroethylene, acetone, or alcohol can be used, either by immersion or ultrasonic cleaning. Non-metallic materials are usually degreased at room temperature by immersion in a degreasing agent for 1.5 to 2 hours, followed by drying in a well-ventilated area until the odor of the degreasing agent disappears.

3. Drying Drying is critical to prevent corrosion caused by residual water. Components can be dried with lint-free cloths or clean nitrogen gas.

4.Inspection after degreasing, the valve surface should be inspected to ensure that it conforms to the applicable standard.

Additional Precautions

In addition to the degreasing process, several precautions should be taken when handling and using oxygen valves:

- Assembly personnel must wear clean cotton work clothes, cotton hats, clean shoes, and plastic gloves (degreased) to prevent contamination.

- Tools used for assembly should be degreased before use.

- After assembly, the valve should be purged with nitrogen for at least 1 minute.

- Leak testing must be performed with pure nitrogen.

- Packaging and shipping should ensure that the valve remains sealed and protected from oil and grease contamination.

In conclusion, degreasing and oil prohibition treatment of oxygen valves is a necessary step to ensure their safe and stable operation. By following a rigorous process and taking the necessary precautions, we can guarantee the performance and safety of these valves, providing reliable support for industrial production.

Athena Engineering S.R.L: A trusted name in valve manufacturing

As an Italian valve manufacturer with a rich history and expertise in valve manufacturing, Athena Engineering S.R.L is dedicated to providing customers with state-of-the-art valve solutions tailored to their specific needs. Our Oxygen Globe Valves are designed and manufactured to meet the highest standards of quality, performance and safety.

With a commitment to innovation and excellence, Athena Engineering S.R.L continues to lead the way in valve technology, ensuring that our Oxygen Globe Valves deliver reliable performance in the most demanding industrial applications. Contact us today to find out more about our products and services.