#Product Trends

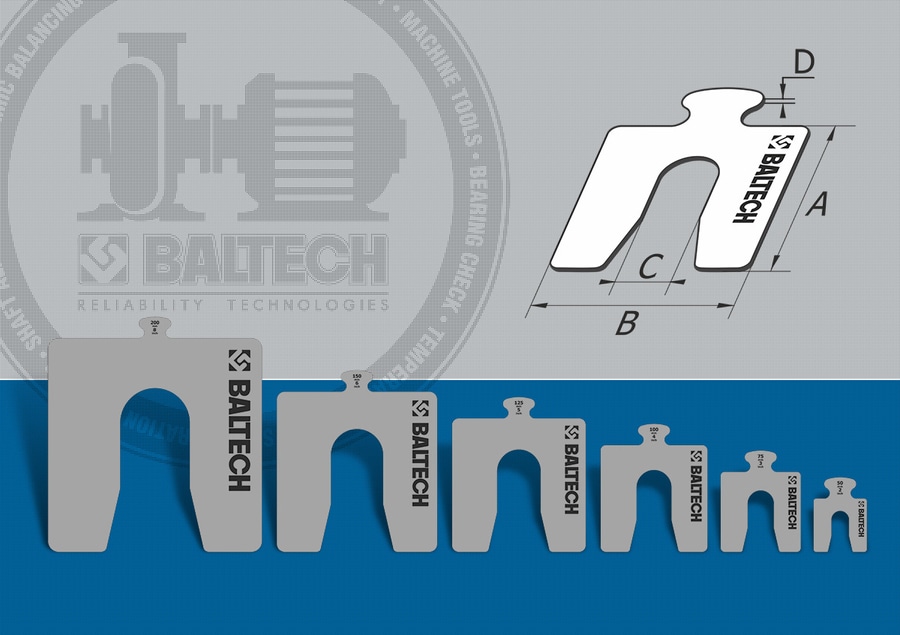

Metal plate with the calibrated plates for alignment

Metal plate with the calibrated plates for alignment of shafts of electrical machines

Company BALTECH GmbH offers new products. Manufacture of calibrated metal plates of any shape according to your order of stainless steel precision thickness of standard AISI 304 (AISI 301).

According to your drawings (diagrams or sketches) we have the ability to produce any shape of plate thickness with a minimum error. Manufacturer of precise mould plates with possible minimum cutout holes is achieved using the laser cutting machine and subsequent primary finishing all edges in mixers with special granules. Our customers order from us manufacture of calibrated metal plates for industrial equipment, plates for alignment of motors, pumps repair, service, fan installation hull bearing, the production of gearboxes.

Our technology of producing grooved metal plates eliminates the deformation or defects. Laser cutting provides high quality and great efficiency even when producing small batches of products even if you want to make one plate. Unlike the standard cut grooved sheet metal stamping standard or, in our method of manufacture of the plates there is no mechanical stress, so the internal and external deformation are absent.

Special machine with laser scissors ensures minimum cutting width even in the thin grooved metal sheet blanks or cut micro-holes, allowing you to accurately, quickly and efficiently produce the finest products.

You only need to send us a drawing or a diagram with dimensions of the desired product, and after consultation with your technical specifications, we need only to digitally program the drawing in an automated laser cutting machine and start the production process.

Company BALTECH GmbH offers you a full cycle of high-level technology in the production of calibrated metal plates. We are able to produce special plates for shaft alignment of electric cars marked with the logo of your company, specify the thickness in millimeters (inches) on each plate, or any other labels using a laser marker. After laser marking all plates automatically are packaged in transparent blister packs.

In advance we ask you to specify the size, location, and text required labelling of each product. Company BALTECH GmbH accepts orders for manufacturing of metal plates of grooved stainless steel sheet metal of fixed size and thickness (0.05 mm; 0.075 mm; 0.10 mm; 0.125 mm; 0.20 mm; 0.25 mm; 0.40 mm; 0.50 mm; 0.70 mm; 1.00 mm; 2.00 mm; 3.00 mm) and in inches respectively(0.002”; 0.003”; 0.004”; 0.005”; 0.008”; 0.010”; 0.015”; 0.020”; 0.027”; 0.039”; 0.079”; 0.118”).

How to place an order for the production of plates or gaskets?

1) Send us a drawing, diagram or sketch showing all the exact dimensions of the needed products;

2) Specify the number of plates and thickness of plates required in the order;

3) Specify the name of the responsible person and his contact details;

4) After calculating your order, our Manager will send you the cost and terms of execution of the order;

5) After signing the agreed final drawing of the plate (strip) we start production;

6) After your order we will send you manufactured the plate in any region;

The production plates in the company BALTECH GmbH using the technology of laser cutting grooved metal sheet, guarantees the workmanship of the ordered products, for a minimal cost and minimum time. For technical designers, technicians and designers, our technology opens you to infinitely wide range of possibilities for the solution of modern and innovative tasks at a high level.