#Product Trends

Material testing with state-of-the-art technology

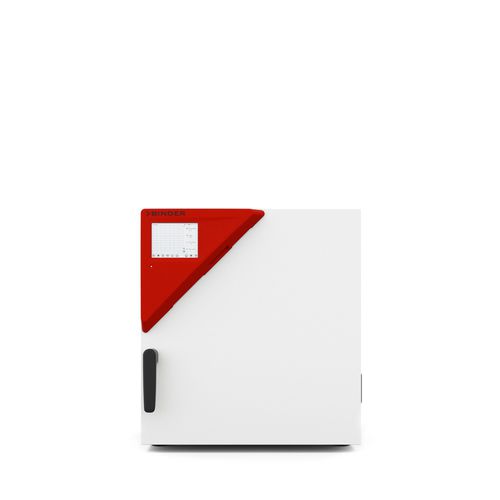

The new generation of BINDER M series drying chambers – more powerful than ever before

The new M series drying and heating chambers set themselves apart with their various programming options and are ideal for material and aging tests.

With a heating up time of no more than 14 minutes and reinforced heating output and ventilation, the new M series units are the most powerful heating and drying chambers in the BINDER range.

Even easier to use

The BINDER controller from the latest generation is the perfect combination of convenience, versatility, and simplicity. The intuitive touchscreen display ensures that the drying chamber is easy to operate and supplies important information during use. As a result, all unit-specific parameters and temperatures can be viewed at all times.

Up to 25 time schedules and five weekly schedules can be stored with supreme ease. This means individualized time schedules with different sequences can start automatically, without requiring the presence of an employee. This is of particular interest to the target groups who have to run and verify corresponding test series to comply with certain standards.

Particularly homogeneous air distribution thanks to modified airflow concept

With the latest APT.line™ technology, BINDER drying chambers are heated constantly and evenly. Reinforced heating output and a reinforced fan combined with the special airflow concept means the new M series offers unparalleled temperature accuracy, improved heating and recovery times, and a more even distribution of heat inside the chamber. For example, the M 56 only needs 9 minutes to achieve a uniform interior temperature of 150° Celsius.

Fan flap control and innovative temperature monitoring

The fan flap can be addressed by the program control and automatically opened and closed at individually defined times depending on the test scenario. For temperature monitoring of the new BINDER drying chambers, the desired mode (independent temperature safety device or independent adjustable temperature safety device) can be selected on the display.

The desired monitoring temperature can be set in “Temperature selection limit” mode and acts as unit and/or goods protection.

Maximum process reliability due to fail-safe

Constant measurement of the temperature in the drying chamber is especially important for achieving perfect drying results. To ensure constant temperature measurement even at temperatures of up to 300° Celsius, two temperature sensors are integrated in all M models. This guarantees that the test series can be carried out flawlessly, even if one sensor fails. The second sensor works as a backup and takes over fully automatically when needed. This prevents unnecessary downtime, and the time until the defective sensor is replaced can be used for additional test series. The sensor failure is recorded and logged by a collective alarm.