#Industry News

Individual sensor solutions often cheaper than conversions

With “MySensor”, Burster offers a unique service for converting all sensors from the portfolio to suit the user's requirements.

In special machine construction or when converting, upgrading or retrofitting existing machines and systems, commercially available sensors often do not fit in the intended position. This can be remedied by a service from sensor specialist burster: in the MySensor department, all force, torque, displacement and pressure sensors from the portfolio can be adapted to the user's specifications or redesigned to suit the customer's individual requirements. It sounds complex, but it is usually cheaper than converting the systems themselves for the use of standard sensors. The procedure also saves time and guarantees optimum measured values. The conversion begins with a feasibility analysis in which CAD data is evaluated. If necessary, the sensor experts inspect the device via video to find the best possible position for force or torque measurement and then agree on the procedure. After the analysis, a prototype is produced, tested and evaluated by the user and then manufactured in series. The materials available are aluminum or stainless steel. They cover a wide range of application requirements and are suitable for special requirements in areas such as hygiene or medical technology. If required, strain gauges can also be integrated directly into customer parts to absorb loads.

Special design cheaper - how does that work?

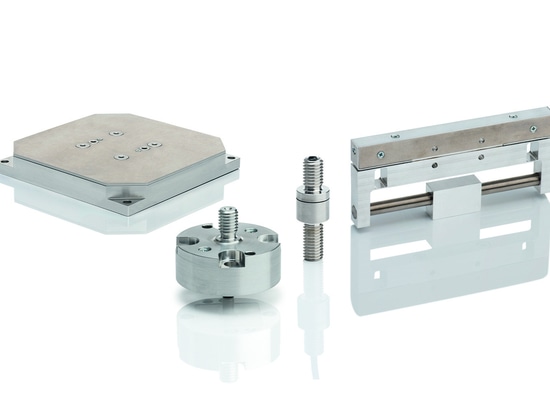

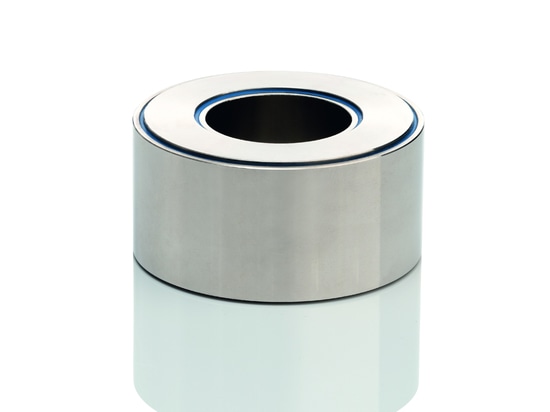

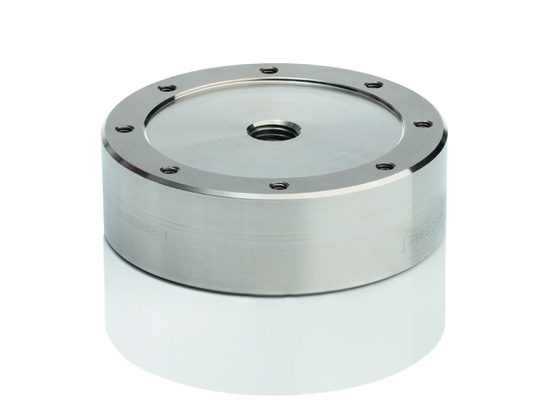

Custom-made products are cost-intensive and therefore undesirable. However, it is often sufficient to adapt the sensor design in order to avoid a mechanical conversion of the machine. This saves time and money. The range of possibilities is wide: housing variations with modified inner or outer diameters, shoulders or flanges or recesses on the housing, modified (through) holes for countersunk screw heads are sufficient in some applications for the sensor to fit. Sometimes fully encapsulated sensor bodies are required to prevent the ingress of foreign particles during injection molding (Fig. 2). One example can be found in motor vehicles, where a sensor with a particularly flat design is required for force measurement on the control pedal (Fig. 3). But even more complicated applications can be implemented quickly with MySensor. Determining the center of gravity of a crane boom truck (Fig. 4) requires insensitivity to vibration and impact as well as integrated low-power electronics and maximum reliability thanks to a fully encapsulated, laser-welded design. The insensitivity to lateral loads is ensured by eight strain gauges. Another complex application example can be found in the measurement of intraocular pressure. Here, small forces have to be measured with low temperature drift (Fig. 5), which was achieved by decoupling the sensor body of the “contact glass dynamometer”.

Info about the pictures:

Fig. 1a and b: Various project-specific sensors, for example for measuring forces and torques (Author: burster)

Fig. 2: Fully encapsulated sensor body to prevent the ingress of foreign particles during injection molding (Author: burster)

Fig. 3: Sensor with a particularly flat design for accurately determining the actuating force of a vehicle control pedal (Author: burster)

Fig. 4: Determining the center of gravity of a commercial vehicle with a crane boom (Author: burster)

Fig. 5: Extremely flat sensor for detecting the smallest forces for measuring intraocular pressure (Author: burster)

Company box: About burster

burster supplies measuring technology ranging from individual sensors to system solutions. Its customers are mainly in mechanical and plant engineering, automation, the automotive industry and its suppliers, electrical and electronic engineering and the chemicals industry. The range includes measuring instruments and testers as well as standard sensors for mechanical and electrical measured values, such as load cells, pressure, torque and displacement sensors, milli- and megohmmeters, and resistance decade boxes. In addition, individual custom OEM solutions are possible, including for many other sectors and future markets such as medical engineering, biotechnology and e-mobility. Many years of experience in designing and building measuring instruments and sensors guarantee optimum solutions every time. Developed and manufactured in Germany, burster sensors, amplifiers and transmitter modules, precision instruments and measuring systems for sensor signal processing are shipped to customers all around the world.