#Product Trends

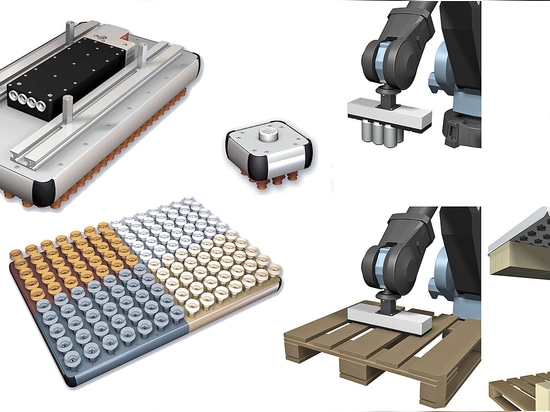

The new MVG Modular Vacuum Gripper series by COVAL : standard made-to- measure.

MVG, what makes the difference

• 100% configurable

• Precise vacuum administration with a "multizoning"

• Savings on every level

100% configurable

The first choice offered to the user is the size. The MVG vacuum gripper series is tailored to the desired size. But customization doesn''t stop there. To benefit from a perfectly adapted gripper, the customer can also configure:

* The vacuum generators

* The gripping interfaces: foam, suction cups (shapes, diameters, diverse materials)

* The vacuum level control: electronic vacuum switch or vacuum gauge

Precise vacuum management with "multi-zoning"

The MVG Modular Vacuum Gripper series allows the creation of multiple independent gripping zones, which guarantees the optimization of vacuum management:

- Increase in vacuum level

- Reduction of leaks

- Drop in energy consumption

This "multi-zoning" is particularly useful for staggered gripping and releasing, handling objects of different formats, or optimization of palletizing layers.

Economy at all level

The high degree of adaptability of this MVG vacuum gripper enables the customer to deal with the majority of situations without having to install several grippers together. For the company, the benefit is threefold: less investment, reduced weight which allows the use of smaller robots and, last but not least, energy savings.

Imminent commercialization

After many tests in laboratories and in real-life use, the MVG series is now at the commercialization phase. Designed for being manufactured as standard, it guarantees short delivery times and high reliability. The Coval team and distributors were trained, prior to commercialization, to enable them to assist customers in their choice of the different options this cavuum gripper provides. This responds perfectly to current trends of solution customization.

Activity fields

Packaging, plastics, metal, glass, wood, concrete/rocks...