#Industry News

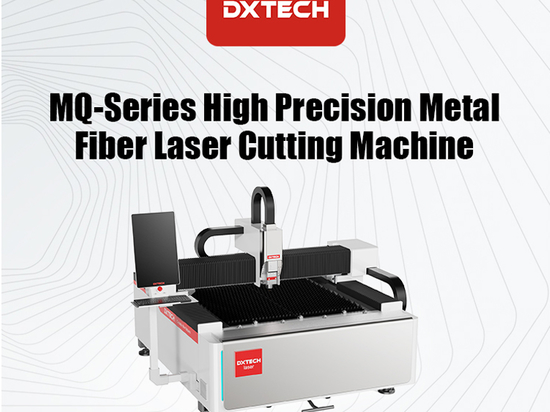

DXTECH Fiber Laser Cutting Machine

Tips and Precautions for Cutting Carbon Steel Using DXTECH Fiber Laser Cutting Machine

Selecting the appropriate cutting parameters

DXTECH fiber laser cutting machines have adjustable parameters such as power, speed, and frequency. When cutting carbon steel plates, choose the appropriate power and faster cutting speed to ensure a balance between cutting quality and efficiency. DXTECH provides multiple laser output powers that can achieve cutting of different thicknesses of carbon steel sheets. The maximum thickness that can be cut with different output powers is shown in the following table. If you want to cut at the critical threshold, we recommend a higher power level to ensure better cutting results.

Preparation

Before starting the cutting process, ensure that the work area is clean and organized, and remove any debris that may interfere with the cutting process. Also, check and calibrate the focus and alignment of the cutting machine to ensure that the laser beam is accurately concentrated on the workpiece, resulting in precise cutting results.

Selecting the appropriate assist gas

Using assist gases such as nitrogen or oxygen can remove the slag from the cutting area and help accelerate the cutting process. When cutting carbon steel plates, choose the appropriate type and flow rate of assist gas to achieve the optimal balance between cutting quality and cutting speed. Generally, if higher cutting speed and efficiency are required, choose oxygen. If the focus is on cutting quality, reducing heat affected zone, and avoiding oxidation reactions, choose nitrogen. In practical applications, adjustments and optimizations may be made based on specific circumstances to achieve the best cutting results.

Controlling cutting overheating

Excessive heating can lead to deformation or decreased quality of the cutting edges. Therefore, when cutting carbon steel plates, it is essential to avoid overheating. Ensure a moderate cutting speed and avoid prolonged dwell time in the cutting area to maintain the quality and precision of the cutting edges.

Safety first

When using DXTECH fiber laser cutting machines, always comply with relevant safety procedures. Wear appropriate personal protective equipment, such as goggles and gloves. Ensure that there are no other personnel around the cutting area and perform regular maintenance and upkeep of the machine to ensure safe and reliable operation.

At DXTECH, we understand your demand for high-quality and high-efficiency cutting. Our fiber laser cutting machines combine advanced technology with reliable performance, delivering excellent results in cutting carbon steel plates. By choosing DXTECH fiber laser cutting machines, you will have an outstanding cutting tool that helps you stand out in the competitive market.