#Industry News

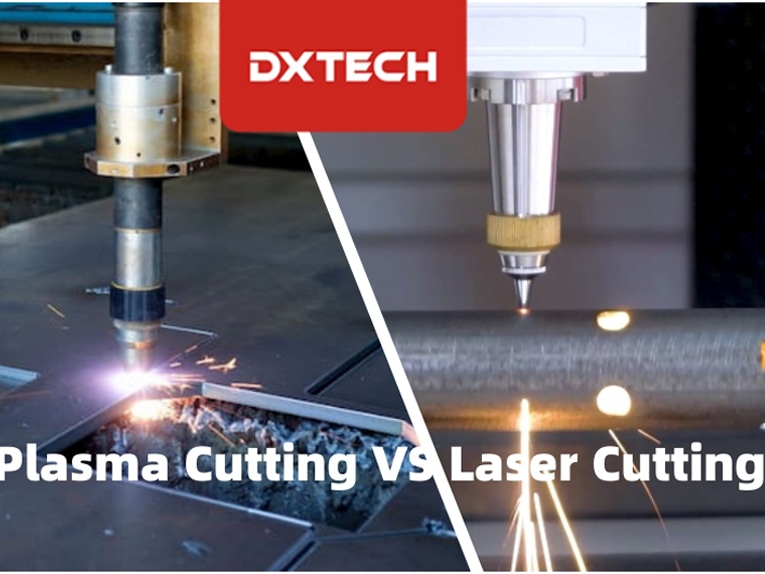

Laser Cutting vs. Plasma Cutting

Laser Cutting Machine vs. Plasma Cutting Machine: Which is Right for You?

Laser cutting machines and plasma cutting machines are two common industrial cutting devices . Although they can both accomplish cutting tasks, their working principles and pros and cons are different. When choosing the right cutting equipment for yourself, it is necessary to first understand their differences.

Differences between Laser Cutting Machine and Plasma Cutting Machine

I. Working Principle

Fiber Laser Cutting Machine

laser-cutting-machine-cuts-10mm-carbon-steel

It uses a high-energy laser beam to cut metal materials.

The laser beam is focused onto a tiny point after passing through a collimator and a focusing mirror, generating high-energy density to heat the metal material above its melting point, and then uses gas to blow away the melted metal.

The fiber laser cutting machine does not contact the metal material during the cutting process, which can reduce deformation and damage during cutting.

Plasma Cutting Machine

Uses a high-temperature plasma to cut metal materials.

Produces a high-temperature plasma through arc discharge to melt and blow away the metal material.

The cutting speed of the plasma cutting machine is slower than that of the laser cutting machine, but it can cut thicker metal materials.

II. Comparison of Pros and Cons

Fiber Laser Cutting Machine

Pros: Fast cutting speed, high cutting accuracy, suitable for various metal materials, smooth cutting surface, contactless cutting, no need to change tools.

Cons: Equipment price is relatively high, high environmental requirements, limited cutting thickness, susceptible to reflection and absorption of metal materials.

Plasma Cutting Machine

Pros: Large cutting thickness, lower equipment price, suitable for various metal materials, faster cutting speed.

Cons: Relatively lower cutting accuracy, rough cutting surface, complex equipment maintenance, susceptible to reflection and absorption of metal materials, easy to produce smoke and noise.

How to Choose Fiber Laser Cutting Machine and Plasma Cutting Machine

When choosing between a fiber laser cutting machine and a plasma cutting machine, several factors need to be considered:

Cutting Material

First, it is necessary to determine the type and thickness of the material to be cut. If the material to be cut is mainly metal and the thickness is relatively thin, a fiber laser cutting machine is generally more suitable. If the metal material to be cut is relatively thick, a plasma cutting machine may be more suitable.

Cutting Accuracy

If high precision cutting is required, a fiber laser cutting machine is the better choice. The laser beam of the fiber laser cutting machine is focused on a very small point, which can achieve high precision cutting. The cutting accuracy of the plasma cutting machine is relatively lower.

Cutting Speed

If high-efficiency cutting is required, a fiber laser cutting machine is also the better choice. The cutting speed of the fiber laser cutting machine is relatively fast, which can achieve high-efficiency production. The cutting speed of the plasma cutting machine is relatively slow.

Equipment Price and Maintenance Cost

The equipment price of a fiber laser cutting machine is relatively high, but due to its high cutting accuracy, fast cutting speed, and low maintenance cost, it may be more cost-effective in the long run. The equipment price of a plasma cutting machine is relatively low, but the maintenance cost is higher.

Conclusion

Both laser cutting machines and plasma cutting machines have their own advantages and disadvantages. If you need high precision, high speed, and wide material applicability, a fiber laser cutting machine is a better choice. If you need to cut materials with relatively large thickness, a plasma cutting machine may be more suitable. DXTECH laser cutting machines are a cost-effective and reliable choice that can meet the industrial processing needs of different scales and requirements.