#Industry News

What are the Reasons Why the Power of Laser Cutting Machines Decreases After Long-term Use?

What are the Reasons Why the Power of Laser Cutting Machines Decreases After Long-term Use?

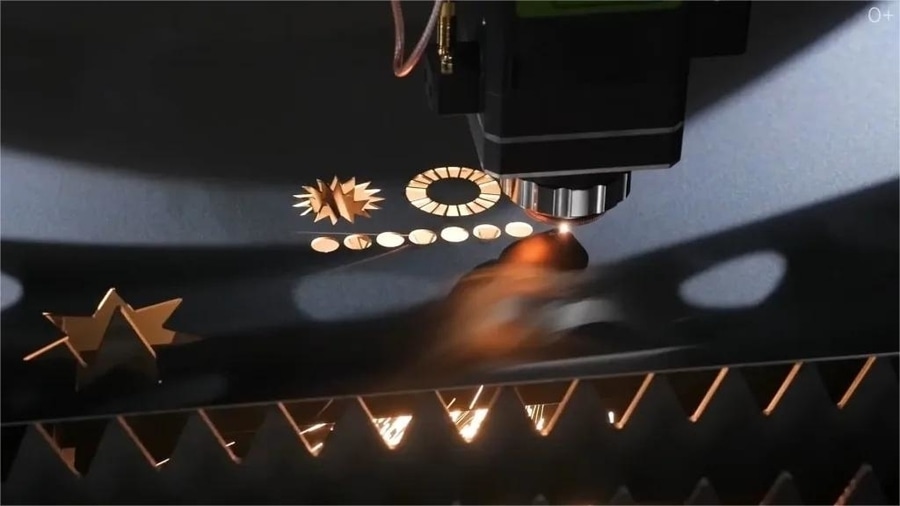

For laser cutting equipment, during long-term use of fiber laser cutting machines, it is inevitable that there will be some losses, such as slower cutting speed and worse cutting accuracy. In fact, there are many reasons that affect the power reduction of laser cutting machines. Today DXTECH Laser will take stock of them for you!

1. Focus position. The focus position affects cutting accuracy, especially the focus spot diameter. The focal spot diameter must be as small as possible to produce a narrow slit. Orui Laser reminds everyone that the focal spot diameter is proportional to the focal depth of the focusing lens. The smaller the focal depth of the focusing lens, the smaller the focal spot diameter.

2. The distance of the nozzle. The distance between the workpiece and the nozzle also affects the power reduction of the fiber laser cutting machine. A distance that is too far will cause unnecessary waste of kinetic energy, and a distance that is too close will affect the dispersion ability of splash cutting products. The appropriate distance is 0.8mm. Orui Laser reminds you that the fiber laser cutting machine mainly relies on its follow-up adjustment to cut workpieces with uneven surfaces. During operation, the height of the nozzle and the workpiece must always be consistent.

3. Cutting speed. The cutting speed has a great influence on the power of the fiber laser cutting machine, and the cutting speed is directly proportional to the power of the fiber laser cutting machine. At the same time, the cutting quality is related to the quality of the laser beam, and it is also related to the characteristics of the laser beam focusing system, that is, the size of the focused laser beam has a great impact on the quality of laser cutting.

4. Auxiliary gas. The size of the auxiliary gas and gas pressure also have an impact on the power of the fiber laser cutting machine. The auxiliary gas uses compressed air or inert gas. Orui Laser reminds you that if the thickness of the processed material increases or the cutting speed is slow, the gas pressure should be appropriately reduced. Using lower gas pressure for cutting can prevent the cutting edge from frosting.

If the first four items have been eliminated, finally check whether the laser power has dropped. The laser is the core component of a fiber laser cutting machine, so the external light path of the laser generator needs to be maintained and maintained regularly. In fact, it is inevitable that the power of the laser cutting machine will decrease after working for a period of time. When the power drops to affect production, the laser and external optical path must be maintained. When the maintenance is completed, the cutting capacity can be restored to the factory level.

In addition, the performance, size and thickness of the materials processed by the laser cutting machine will also affect the power reduction of the fiber laser cutting machine. DXTECH Laser reminds you that when using fiber laser cutting machines, we must pay more attention to daily maintenance, and we must fully understand the reasons for the attenuation of fiber laser cutting machines and take corresponding measures, so as to extend the service life of fiber laser cutting machines.