#Product Trends

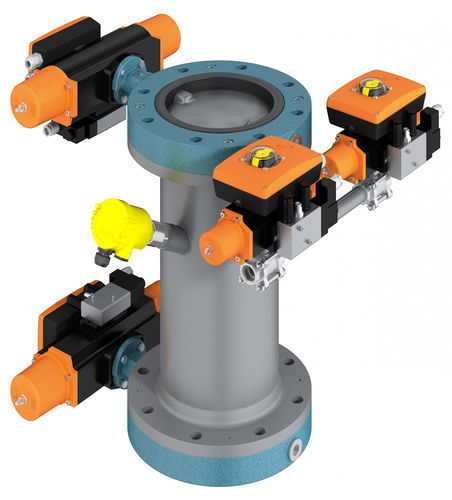

Ready for Anything: The EBRO Impeller Valve Type FS-M

Valves for high-precision control and dosing in powder and bulk material applications

Rotary impeller valves are used in bulk processes in order to ensure uniform discharge of materials , e.g. from silos, bunkers, weighing hoppers, etc. Due to its frequency-controlled rotational speed, it also functions as a dosing unit that operates volumetrically and also effectively prevents overfilling of downstream process sections. If the wing sluice is used in pneumatic conveying lines, it homogenizes the product flow.

The six blades of the impeller of the EBRO FS-M run through the zero line of the body. Materials passed through are neither scraped and pressed along the front side nor laterally along the body walls, nor can granules be pulverized. The FS-M is therefore extremely gentle on the product and energy-efficient. All parts in contact with the medium are made of FDA-compliant stainless steel or are designed according to customer requirements. The FS-M is available in DN 150-DN 500.