#Product Trends

How FPI Processes Infrared Thermal Imaging Technology

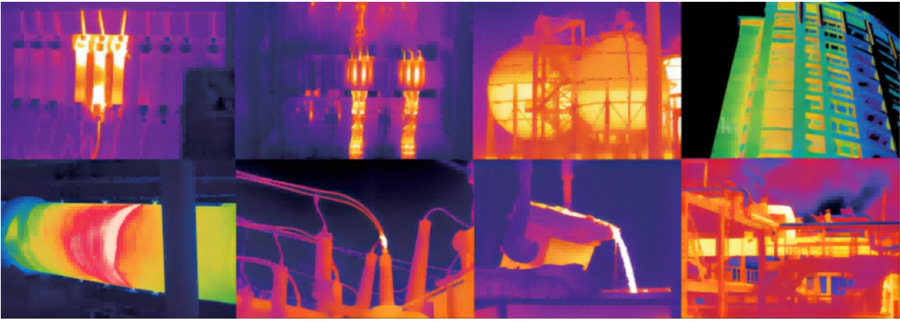

Infrared thermal imaging is a passive, non-contact infrared technology.

All objects in nature whose temperature is higher than absolute zero (-273°C) radiate infrared rays at all times, and infrared radiation carries the characteristic information of the target object. The spatial distribution of the object's surface temperature is processed by the photoelectric infrared detector to form a thermal image and converted into a video image, forming a thermal image corresponding to the thermal distribution of the object surface, that is, an infrared thermal image.

Infrared thermal imaging technology cannot reflect the appearance of the object but the thermal contour. It has the following features compared to traditional monitors:

1. Night vision adaptable

2. Can use days and nights

3. Can use in extreme weather

4. Can see through barriers like smog, rain, and smoke

The technology boasts a wide range of applications. Its development also boosts industries like energy, metallurgy, and petrochemical to transform to be more scientific and safer. The technology is also used for scientific research and urban city management. Generally, it is meaningful for modernization in different industries. FPI, as the manufacturer of advanced monitoring equipment, has its own products based on the technology.

Online Infrared Monitors/System Recommendation

FPI provides 10-ish infrared monitors or systems for different use, and here present the three of them.

· F-3/F-6 Smarteye Series Infrared Surveillance/Monitoring System

The system is of different resolution, with F-3 384 x288 17μm and the other 640 x480 17μm. The monitoring system enjoys a wide temperature range from -20℃~350℃, which can also be extended to 1500 ℃ based on the actual demands. It also has the following features:

1.High accuracy: minimized variants: ±2℃ or ± 2%

2.Multiple lens options: 75mm, 50mm, 35mm, 25mm, 19mm, 13mm, 9mm

3.Multiple thermal image analysis types: Regional temperature abnormal alarm, motion detection, intrusion alarm, etc.

4.Rugged design: well-designed and certified to IP66, and can withstand high humidity up to 95%

· F-3FD/F-6FD Explosion-Proof Dual-Spectrum System

It is an Infrared detector of uncooled micro-pyrometer that can offer high-temperature checking and extreme temperature alarming with the following features:

Digital zoom is allowable to care for both microscopic details and macroscopic situation

1.High accuracy: minimized variants: ≤60mk

2.Strong lighting and heating resistance

3.Real-time monitoring

4.Rugged design: well-designed and certified to IP66, and can withstand high humidity up to 95%

· V-3 Gas Leak Detecting Thermal Imaging Camera

The cooled detector is for gas detecting, which can be used in various scenarios such as petrochemical plant,oil & gas reservoir and natural gas pipeline to keep an eye on safety and green production. It also has the following advantages:

1.High accuracy: minimized variants: ≤15mK@15°C

2.Detectable Gases: Methane, ethane, propane, butane, ethylene, propylene, benzene, ethanol, ethylbenzene, heptane, hexane, isoprene, methanol MEK, MIBK, octane, pentane, 1-pentene, toluene, xylene, etc

3.Detectable even when the object is in a moving situation

4.Wide measurement and analysis range: -20°C~350°C

FPI's Infrared Monitoring System's Application to the Steel Industry

The monitors are a great detector for the steel industry to ensure working safety and prevent any emergencies since factory accidents are always costly. It is versatile in multiple process steps such as Ladle Monitoring,Defect Monitoring of Converter, Slag Bag Monitoring,Defect Monitoring of Converter and Hot-blast Stove Detection. Here are detailed descriptions of its application in two aspects.

· In hot-blast stove detection

The temperature of the blast stove surface turns out to be extremely different considering the damages to various extents of the stock wall. It makes finding the burned position a headache. However, procrastinating fixing may damage production and leave a time bomb. In this aspect, FPI's infrared monitoring system for this field has the following features:

1.Wide coverage to be able to observe the temperature field distribution and present with intuitive colors

2.Intelligent information collection and analysis for warning the abnormal area. And can trace the data history for comparison.

3.Online management allowable: the calibration can be made online

· In roll monitoring

Roll enjoys a huge consumption in steel production. However, its constant contact with the red-hot steel billets makes it prone to defects, affecting steel production. Therefore, the infrared monitoring system is for checking the abnormal heating area of the rolls to do some protective measures. FPI's infrared monitoring system's advantages can be seen in the following aspects:

1.Wide coverage

2.Straightforward looks at the temperature distribution of the roll, from minimum to maximum

3.No blind spots are hidden. Customization allowed