#Product Trends

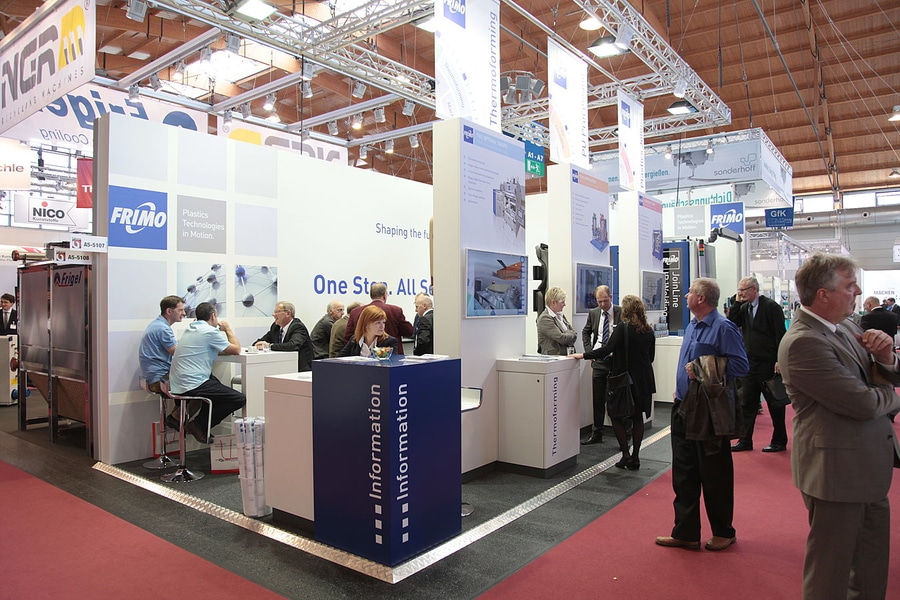

FRIMO presented innovations in plastics joining, thermoforming and PU processing at the Fakuma

Among topics were:

And everything fits - flexible seat cushion production with FRIMO PURe Floor

With PURe Floor, FRIMO has developed a modular and flexible production system that can be set up using a standardized construction kit. The PURe Floor solution has already proven its worth for the automated manufacture of car seats. It can also meet the demands presented by a variety of other applications - headrest production for example.

When manufacturing car seats from polyurethane, there are a series of requirements that must be met. This usually involves the mass production of soft foam formed components, possibly with varying compressive strengths. Foam is applied through mixing heads capable of working on up to 6 components, usually in open molds using robots that move in precise paths. In today''s standard production systems with mold carriers, usually the foam pieces for the front and back seats are produced in the following constellations: Every mold carrier is capable of accommodating two molds for two front seats, two molds for symmetrical or asymmetrically divided back seats, or one form built for the manufacture of the seats or seat backs of a one-piece rear seat. In fast-running production facilities for seat cushions, production cycles as short as 8 s per mold carrier are being achieved, meaning the production cycle per front seat component is 4 s or 8 s per mold piece for one-piece back seats.

The increasing diversity of variations available within the individual car model series added to the fact that seats are most often produced by suppliers and then delivered to the respective assembly lines of the OEM just in time, customers almost always have a need for higher flexibility and faster production adaptability when it comes to system concepts. For mass production only continuous conveying concepts make technical and economic sense.

For further Information www.frimo.com.