#Product Trends

Revolutionizing Motion Control with Linear Motors

9 major components comprise linear motor systems.

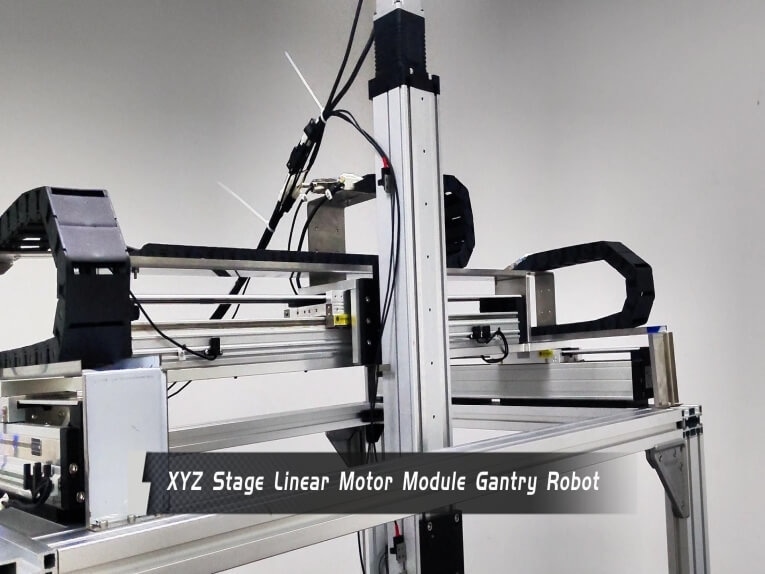

XYZ Stage Linear Motor Module Gantry Robot

Linear motors have redefined what’s possible in motion control with faster, more precise, and more reliable performance compared to traditional, rotary motor-driven linear actuators. A linear motor’s unique property is that the load is moved without mechanical power transmission components. Instead, the linear force generated by the magnetic field of the motor coil is directly coupled to the load. This eliminates mechanical devices that convert rotary motion to linear, thus enhancing the system’s life, precision, speed, and overall performance.

As the demand grows for increased productivity, higher product quality, rapid development time, and lower engineering costs, adopting linear motor technology is increasingly popular by leveraging modular linear motor designs. They are found in metrology, precision cutting systems, semiconductor and electronics manufacturing equipment, wafer handling, lithography, vision inspection systems, medical equipment and devices, test systems, aerospace and defense, assembly line automation, printing and packaging applications, and many other applications that require high throughput and high-accuracy linear motion.

The components of a linear motor design need to be machined and assembled with high precision and repeatable processes. Proper alignment of these parts is critical and requires significant design detail and assembly skill.

Today, the new generation of modular linear motors has changed the game. Turnkey modular linear motors can be easily bolted onto a system and are ready to run immediately, significantly reducing engineering time. Engineers can now leverage the powerful benefits of modular linear motor technology into their machine designs in mere days, as opposed to months or even years.

Nine major components comprise linear motor systems:

1. A base plate

2. A motor coil

3. A permanent magnetic track (normally neodymium magnets)

4. A carriage that connects the motor coil to the load

5. Linear bearing rails that the carriage is guided on and connect to the base

6. A linear encoder for position feedback

7. End stops

8. A cable track

9. Optional bellows to protect the magnet track, encoder, and linear rails from environmental contamination.

CONTROL LOOP

The components of a linear motor design need to be machined and assembled with high precision and repeatable processes. Proper alignment of these parts is critical and requires significant design detail and assembly skill. For example, the magnetic track and moving motor coil must be flat, parallel, and mounted with a particular air gap between them. The moving coil rides on a carriage connected to parallel precision linear bearing rails above the magnetic track. The position encoder with a linear scale and read head is another critical part of a linear motor that demands proper alignment procedures and a robust mounting design to withstand accelerations up to 5 Gs. With modular linear motors, these details are already accounted for and pre-engineered out of the box.

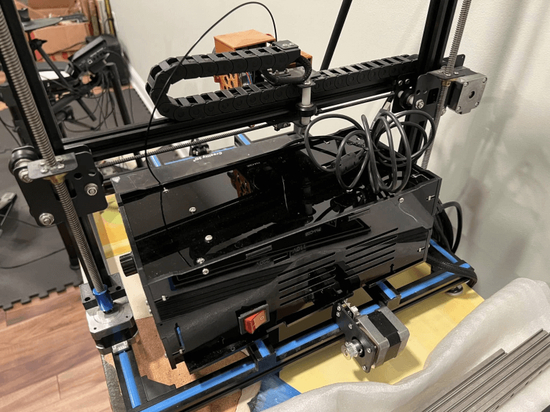

Modular linear motor systems like the one shown are used when precise, high-speed, and repeatable linear motion is needed. The system is an alternative to ball screw, belt, and rack and pinion actuators.

Sophisticated motion controllers and servo drives are used to control the motion of the linear motor. Linear motors hold a definite advantage regarding stiffness and frequency response. In certain frequency ranges, they exhibit a stiffness that surpasses traditional ball screws by a remarkable factor of 10 or more. With this attribute, linear motors can handle high position and velocity-loop bandwidths with impressive precision, even with external disturbances. Unlike ball screws, which often encounter resonant frequencies between 10 and 100 Hz, linear motors operate at higher frequencies, placing their resonances well beyond the position loop bandwidth.

However, there is a trade-off associated with the removal of mechanical transmission. Mechanical components, such as ball screws, help decrease disturbances from machine forces, natural resonant frequencies, or cross-axis vibrations. Their elimination leaves linear motors directly exposed to such disruptions. Consequently, compensating for these disturbances becomes the responsibility of the motion controller and drive electronics, which must tackle them head-on — acting directly on the servo axis. That’s where today’s sophisticated closed-loop motion algorithms come into play to eliminate resonances and provide remarkable position loop control.

Within the realm of linear actuators, linear motors provide exceptional technical prowess. The motors’ ability to exhibit superior stiffness and operate at higher frequencies sets them apart from traditional alternatives. By defying resonant frequencies and maintaining high precision even in the presence of external disruptions, linear motors offer a compelling solution.

Nevertheless, the absence of mechanical transmission necessitates robust compensation strategies to counteract disturbances, ensuring the system’s continued performance and reliability. Motion controller sampling frequencies for velocity and position loops typically begin at 5 kHz. A linear motor axis can have a position loop bandwidth five to ten times that of a conventional rotary motor-driven axis, where 1 or 2 kHz frequencies are acceptable. Some current motion controllers can sample rates of 20 kHz or greater, which enables ultra-highspeed feedback control and ultra-precise path control.

Since most manufacturers of modular linear motors are also motion control and servo experts, many control loop challenges and mechanical resonance concerns have also been well thought out, and solutions and tools are provided to mitigate these challenges.

LINEAR MOTOR APPLICATION

I gained valuable experience using linear motors years ago, with a team of engineers embarking on a revolutionary project: to create the world’s first linear motor-based laser cutting machine. Using linear motors was the perfect fit to disrupt the industry, as traditional linear actuator technologies driven by rotary servo motors couldn’t provide the high-performance capabilities achievable with linear motors.

Implementing the technology was not an easy task. As we dug into the project, we realized that our application required linear motor performance specifications that were not commercially available. Undeterred, we decided to design linear motors specifically for our application.

We faced numerous challenges, as we needed to move a 1,000 lbs gantry system at a rapid rate of 2.5 m/sec with 1.5 G acceleration, meaning we had to design a linear motor that could produce extreme forces. Our team persevered, pouring countless hours into research and development until we finally devised a linear motor that could meet the demands of our laser-cutting machine. It was a proud moment when we finally saw our linear motors in action 14 months later, propelling the gantry system with incredible speed, ease, and precision. The performance achieved was unprecedented. It’s remarkable to consider how much faster our machine concept could have been completed if turnkey modular linear motors were available then.

Linear motor technology has greatly evolved since we embarked on a linear motor design journey in the ‘90s. With the introduction of new modular designs, the potential for innovation and progress in motion design and linear motors is greater than ever. Modular linear motors are redefining what’s possible, with faster, more precise, and reliable motion control capabilities that can be deployed rapidly to benefit a wide range of applications in many industries.