#White Papers

7 Challenges In Industrial Robotics

Costs, Inflexibility, Safety Concerns, Workforce Skills, Workforce Training, Managing Workflows, Latest Advances.

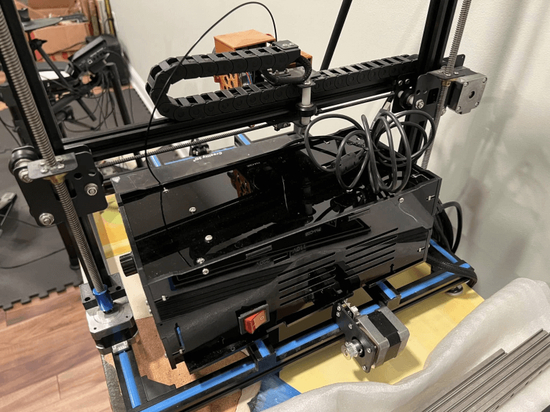

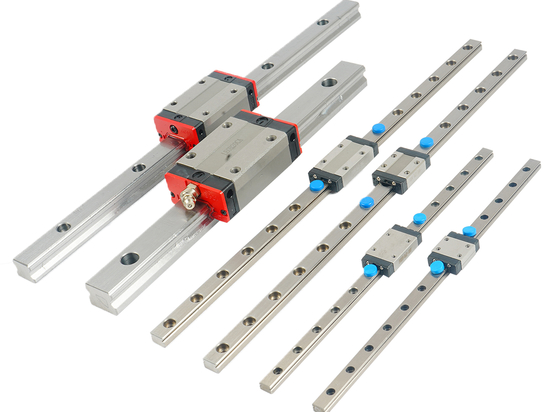

From a simple robotic arm to widespread implementation, there have been many challenges for industrial robots to overcome, including high prices and complex hardware. Early examples were hampered by their infrastructure, having to rely on things like tracks, rails or magnets. They also relied on battery power, which seriously limited their range and performance.

In the past two decades, the impetus of Industry 4.0 has pushed developments ahead at a much faster pace. This doesn’t mean that it’s all plain sailing from here on in – and many challenges in industrial robotics still remain. These seven are the most common:

Costs

The high costs of implementation are one of the major challenges when installing industrial robotics. The initial integration process is likely to be long, arduous and expensive. The specifications of new tasks may require redesigning the workspace and repurposing robot workers. Even minor modifications to a manufacturing line may demand a specialist integrator.

Trying to implement new robotic systems with existing infrastructures and technologies isn’t easy for large concerns. Smaller-scale SMEs often find the costs unjustifiable or prohibitive. In addition, production volumes and sales levels need to be sustained during the expected ROI period to recoup the initial investment.

Inflexibility

This lack of coordination is a further challenge in industrial robotics. A single manufacturer will not only provide its own hardware, but its own software solutions. Numerous application programming interfaces are then required to coordinate across different devices, and may even necessitate custom software. Current robotics technologies can’t always be easily repurposed, which limits the robots’ potential roles. Even knowledgeable and experienced line workers are often unable to improve manufacturing processes by this means.

Greater flexibility would allow robotic systems to cope with faster integration and reintegration times and robot reusability. It could also enable reconfigurable manufacturing lines and work cells, plus the opportunity for high-mix and low-volume production. A factory’s energy footprint could be reduced by manufacturing multiple products using a single production line.

Safety Concerns

New tech demands new procedures, and these immediately introduce new safety hazards into the workplace. Industrial robots are no exception and there are strict regulations surrounding robotic safety, as well as severe penalties.

Before integrating any industrial robot system, manufacturers have to prepare for this and be ready to create a safe environment for workers that ensures full compliance. Investment in industrial robots would be encouraged if manufacturers could find an optimal balance between safety, versatility and speed.

Workforce Skills

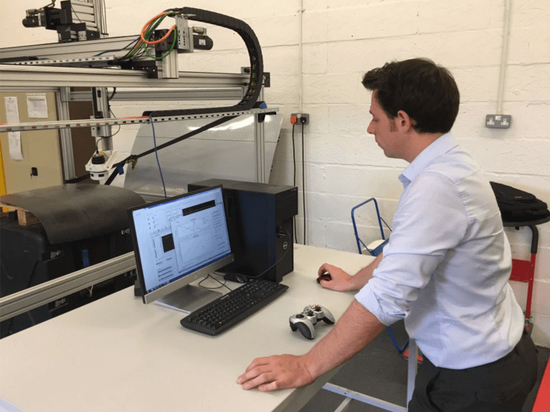

Operators also have to acquire a new level of expertise. Workers don’t usually understand how to operate new types of equipment and, in the case of mobile robots, they don’t know how to behave correctly around them. They often get in the way of a robot’s path or are confused about the allocation of activities between humans and automated workers.

The technology is still relatively new, so there’s no embedded academic training as you’d find with older skills. Many employees will therefore require training, and in the meantime, other staff will need to be hired who already possess the requisite education, certifications and experience.

Workforce Training

Industrial robots are intended to enhance a facility’s overall performance. This means that they must interact with humans in a mutual dependency. Until staff acquire the necessary skills, the facility will be much less efficient and therefore less cost-effective. Basic robotics training will raise employee awareness of how robotic systems behave and how humans should respond. Overall efficiency can be improved by demonstrating the co-dependence of humans and industrial robotics.

This can be assisted by using advanced analytics and data collection to identify key issues. As much data as possible should be gathered by operators, including what and how many journeys are made by robotic systems, downtime experienced due to errors and bugs, battery-charging times, and time spent idling. Using this information, operators can adjust the necessary processes to target specific problems and increase robot efficiency.

Managing Workflows

Product workflows need to be evaluated to see what gains could be made by integrating robots. This includes calculating the speed and orientation of part presentation to robots to ensure maximum productivity, without overloading existing systems. Anecdotal and experiential evidence from workers can be submitted to data analysis to improve the workflow and assess how their contributions affect design and integration processes. This could also help evaluate the overall effect on performance and production cycles, to eliminate inefficiency.

Latest Advances

While they may serve all sorts of purposes, the issues in industrial robotics are relatively similar. With all the technological developments of Industry 4.0 that support modern robotic systems, many of these challenges are being addressed.

With better training, people will have a greater understanding of how robotic platforms work. In the long run, more people will acquire the requisite skills and could learn how to develop their own robotic platforms. Programming solutions are being developed that use open-source environments, as well as no-code or low-code solutions.

Robotic developers are beginning to focus more on situation awareness, with complex sensory arrays that greatly enhance the intelligence of cobots. They’ll be able to understand their surroundings better and learn how to behave around humans, just as humans will learn how to behave around them. The net result is improved robotic interactions that increase productivity and reduce costs.