#Product Trends

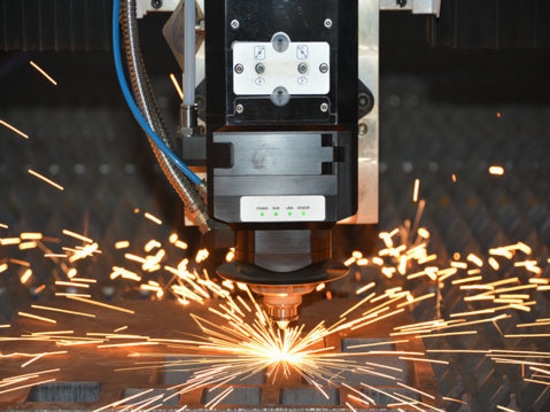

New Arrival: Ground Rail Laser Cutting Machine with Large Format

Large processing area, cutting thick sheet metal easily, safe and environmentally friendly.

Laser cutting is a technology that uses a laser to vaporize materials, resulting in a cut edge. It is typically used for industrial manufacturing applications.

Why ground-rail laser cutting machine?

1. Mainly for customers who need large-format thick plate cutting, you can choose the fiber laser from 6000w to 30kW. It can realize the timely processing of various graphics and characters and is user-friendly and straightforward.

2. Applicable:

● Rail transit, shipbuilding, construction machinery, agricultural and forestry machinery, electrical manufacturing, textile machinery, tool processing, petroleum machinery, mining machinery, food machinery, laser metalworking services, and other manufacturing and processing industries.

● Carbon steel, stainless steel, aluminum alloy, brass, copper, galvanized sheet, silicon steel sheet, electrolytic sheet, titanium alloy, manganese alloy, etc.

3. Standard laser machine format:

X-axis travel: 2.5m/3.5m/4.5m/5.5m

Y-axis travel: 4m to 48m (4m is a unit)

What are the features of a ground-rail laser cutting machine?

✔ Fast speed and high precision;

✔ Ultra-large format, wider application of incoming materials, to meet more market demands;

✔ Modular structure, which is convenient for disassembly, installation, and transportation;

✔ Cost-effective, lower cost than traditional laser cutting machine tools of the same size;

✔ More safety, with a safety grating to avoid personnel being collided by the beam during the picking process;

✔ Better dust removal and more environmentally friendly.

✔ Laser cutting accuracy is guaranteed, with steel plate welded machine bed, high-performance aluminum beam, the integral structure at the end.