#Industry News

Case Share: 20kW Laser Cutting Machine for Steel Structure Connections

Laser cutting automation solutions change your productivity

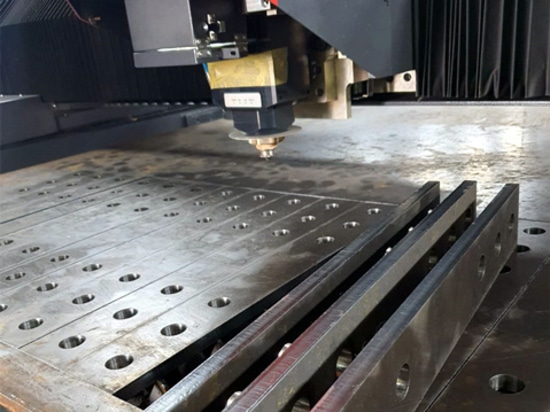

Steel connections are bridges between the various components in the steel structure. They connect the individual steel components tightly together to form a complete structure. This connection not only ensures the stability and integrity of the structure but also enables the steel structure to withstand various external loads. Through the connectors, the steel structure can resist external forces such as wind and earthquakes as a whole, thereby improving the overall stability and safety of the structure.

Traditional processing methods for steel structure connectors:

• through plasma cutting, shearing machines, and other processing methods to scoreboard square or rectangular connectors of different sizes.

• according to the design dimensions, the center positions of the mounting holes of the individual connectors are marked in turn.

• manually hammered one by one to punch holes, ensuring the convenience and accuracy of subsequent manual drilling.

• before drilling a hole, test and drill it. Align the drill bit's chisel edge to the center of the hole and drill a shallow hole.

Pain points of traditional processing methods:

• poor processing quality

• serious waste of materials

• poor machining accuracy

• low efficiency

• complex process

Golden Laser realizes batch automated connector processing:

1. Loading of the raw material: manual or automatic loading devices

2. Drilling holes in connecting parts: a CNC drilling machine is used to drill the installation holes. At the same time, two positioning holes are added to the waste area at the edge of the plate.

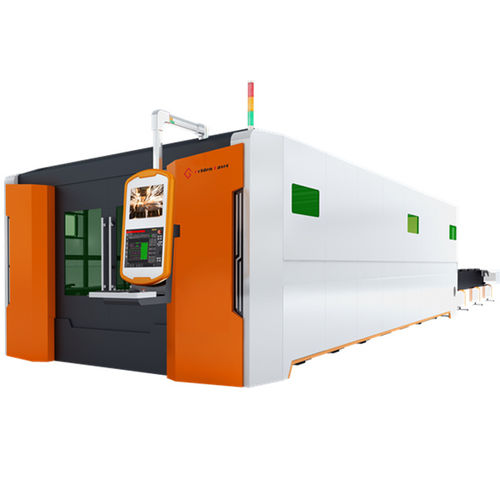

3. Laser cutting of steel structure connection profiles: the visual recognition system of the Golden Laser "M" series fiber laser cutting machine can automatically identify the positioning holes on the whole steel plate. Our customized laser cutting system is compatible with customers' existing LANTEK, CNC, and other nesting software, which can seamlessly convert drilling and nesting drawings into cutting programs, and achieve high-precision, high-quality, and fast cutting of the shape of the whole plate connector.

4. Mark point positioning to achieve precise cutting. Plates can be placed at will, the processing position can be immediately locked, without tedious secondary adjustments, and the cutting process can be started directly. This optimization not only significantly improves processing efficiency, but also greatly reduces dependence on manual operations, saving labor costs.

5. Laser automatic rust removal

Contact us with your metal processing project and we will customize your laser solution!