#Industry News

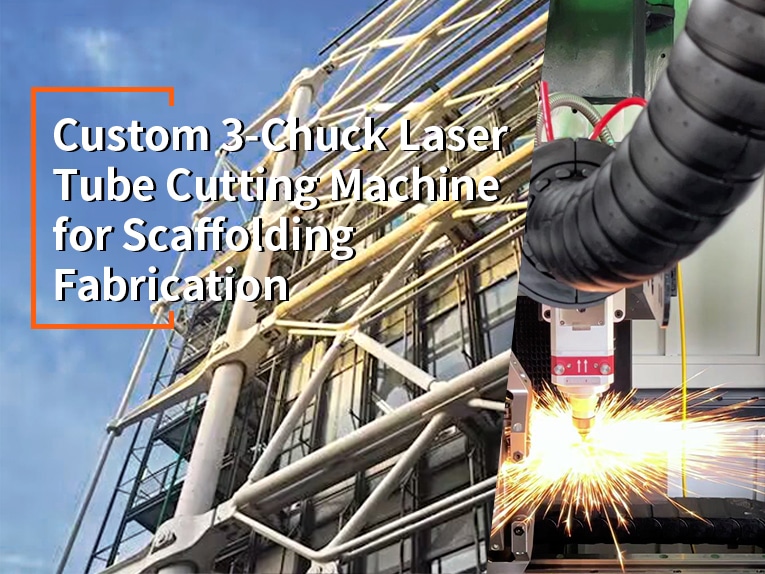

Case Share: Custom Ultra High Precision Laser Tube Cutting Machine with 3 Chuck for Scaffolding Manufacturing

Custom Laser Service Near You

Precision, efficiency, and versatility are paramount in the competitive field of scaffolding manufacturing. A leading scaffolding manufacturer enhances their production capabilities by investing in a custom ultra-high precision laser tube cutting machine equipped with three chucks.

Objectives:

• Increase Precision: Achieve ultra-high precision cuts to ensure the highest quality scaffolding components.

• Enhance Efficiency: Reduce production time and increase throughput.

• Versatility: Accommodate a wide range of tube sizes and materials.

• Automation: Minimize manual intervention to reduce labor costs and human error.

• Solution: Custom Ultra High Precision Laser Tube Cutting Machine

Key Features of 3-Chuck Laser Tube Cutting Machine S12plus:

• Enhanced Stability: The three-chuck system provides superior stability and precision during cutting, ensuring minimal deviation and high-quality cuts.

• Versatile Clamping: Capable of securely holding tubes of various diameters and materials, from steel to aluminum.

• Ultra-High Precision Laser:

Utilizes a state-of-the-art fiber laser capable of cutting with micron-level precision.

• Adaptive Optics: Automatically adjusts the laser focus to maintain optimal cutting conditions for different materials and thicknesses.

• Automated Loading and Unloading:

Smart Loading and Unloading System: Ensures smooth and continuous material flow, minimizing downtime.

• Intelligent Control System:

CNC Integration: The machine is controlled by a sophisticated CNC system that allows for precise programming of cutting patterns and sequences.

• Real-Time Monitoring: Equipped with sensors and cameras to monitor the cutting process in real-time, ensuring immediate detection and correction of any anomalies.

•User-Friendly Interface:

Touchscreen Display: An intuitive touchscreen interface allows operators to easily program and control the machine.

• Remote Access: Enables remote monitoring and troubleshooting, reducing the need for on-site technical support.

Benefits

• Improved Precision and Quality:

Achieved ultra-high precision cuts, resulting in scaffolding components with superior fit and finish.

• Reduced material waste due to precise cutting, leading to cost savings.

• Increased Efficiency:

Significantly reduced production time, allowing the manufacturer to meet higher demand and take on more projects.

• Automated processes minimized manual intervention, reducing labor costs and the potential for human error.

• Enhanced Versatility:

The machine’s ability to handle various tube sizes and materials provided the manufacturer with greater flexibility in their product offerings.

• Enabled the production of more complex and customized scaffolding designs.

•Operational Reliability:

The robust design and intelligent control system ensured consistent performance and minimal downtime.

•Real-time monitoring and remote access capabilities facilitated proactive maintenance and quick resolution of issues.

Conclusion

The custom ultra-high precision laser tube cutting machine with a three-chuck system has revolutionized the scaffolding manufacturing process for the client. By significantly enhancing precision, efficiency, and versatility, the machine has enabled the manufacturer to produce higher-quality scaffolding components, reduce costs, and increase its competitive edge in the market. This case exemplifies the transformative impact of advanced manufacturing technology in the scaffolding industry.