#Product Trends

What is an MES system?

The MES System allows you to organise, control and monitor production processes in real time.

Production processes in any sector as well as in the so-called Industry 4.0 are complex. That is why it is important to have a system in place to optimise production processes and make the best possible use of available resources.

The Manufacturing Execution System (MES) is a production management software developed to organise, control and monitor production in real time. In this way, it is possible to reduce costs, achieve the maximum possible efficiency, as well as improve traceability and the quality of the final product.

In this post we are going to talk about the advantages of the mes system as well as which industrial computers are the most suitable for the installation of this programme.

What is an MES system for?

MES systems can manage a large number of processes, and offer a series of functionalities that allow you to supervise and take greater control of the production process. Some of the functions of the MES system are:

Activity sequencing: the MES system establishes the order of the operations to be carried out according to the priorities and characteristics of each manufacturing batch. This avoids downtime, optimises the use of resources and ensures that deadlines are met.

Task monitoring: this production management software allows real-time control of production, i.e., it allows you to know which tasks are being carried out at any given moment (Work in Progress). In addition, it detects possible problems that may be occurring in the production process, bottlenecks or deviations in relation to the planned plan. The MES system thus helps to take the most appropriate decisions to correct any anomalies detected, improving production control over the process.

Automatic data collection and document management: the Mes System automatically collects all the important information on the processes, materials and operations carried out either by the workers or by the machines. This collected data is stored in a centralised database and can be consulted at any time.

Analysis of process performance: The Mes System allows you to examine the collected data by comparing it with the data you have already recorded. This makes it possible to evaluate the performance of the processes, the resources dedicated to each task, the time spent, whether or not the planned schedule has been met and the costs.

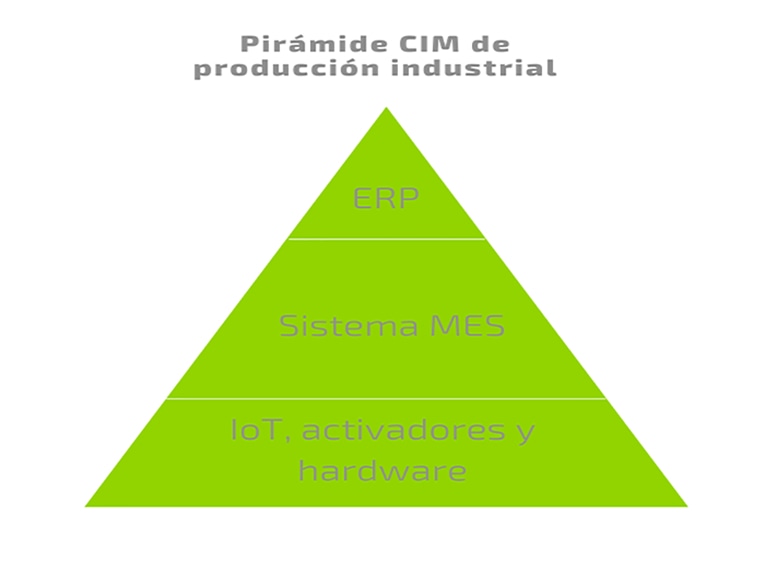

Integration with other systems: this system communicates and exchanges information with other computer software such as ERP (Enterprise Resource Planning) or Warehouse Management Systems (WMS).

Requirements needed to install the MES system

As we have just explained, the MES system has several advantages, such as making it possible to control production in real time or to monitor tasks in a factory or any company in the so-called Industry 4.0.

Now we are going to see what requirements the computer on which this production management software is going to be installed must have.

These are some of the requirements necessary for the installation of the MES system:

Operating system: the MES system can be installed on Windows, Linux and Android compatible computers.

Processor: The computer's processor must be powerful enough to support the execution of the MES system and all production management applications.

RAM memory: the RAM memory capacity required for the installation of this production management software will depend on the size of the plant and the number of production lines.

Network card: a network connection is needed to connect the production equipment to the computer.

In the EOS Ibérica Group we have the ePX MES RFID equipment, a 10.1" and 11.6 capacitive industrial touch panel PC, with a Realtek RK3288-I Cortex-A17 Quad Core 1.8GHz processor, 2 gigs of RAM, EMMC and compatible with Android 7.1, 10.0 and Linux OS.

This rugged industrial computer is fully compatible with the MES system. It has a 730P camera and 13.56 MHz RFID/NFC reader for operator identification.

For more information about this industrial computer or any other computer component, please contact us. Our technical team will be pleased to help and advise you.