#Trade Shows & Events

More efficiency and safety: Combined mast and support control with CAN bus from HAWE Hydraulik

18.03.2025, Munich

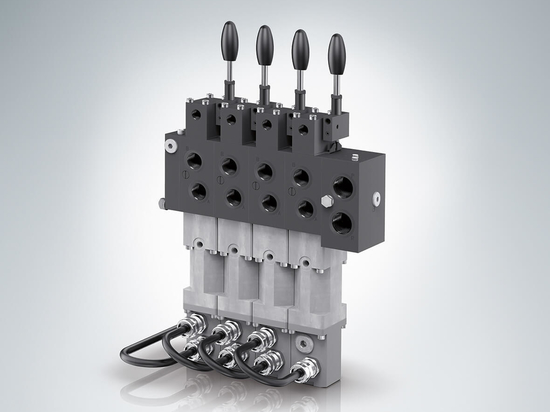

In mobile machinery, there are often functions that can run in sequence or even have to for safety reasons. With the MICK control block, HAWE Hydraulik has a compact and high-performance solution for this in its portfolio. Originally developed for the boom control of concrete pumps, size 2 is now coming onto the market following the successful market launch of size 3 with up to 120 l/min/consumer. This is even more compact and therefore particularly interesting for smaller spider platforms and aerial work platforms where a volume flow of up to 60 l/min per consumer is sufficient.

The innovative directional control valve bank offers two major advantages for developers of mobile machines. On the one hand, it is very small due to its integrated design and makes commissioning easier with its preconfigured functions. On the other hand, the connection of a 4/3 directional control valve with a downstream switch enables safety functions to be implemented. Specifically, a MICK section consists of a 4/3 directional control valve and a directly flanged switch, thus combining the function of three separate control blocks in one. This means that up to three double-acting consumers can be supplied with one valve section. Up to eleven valve sections can be combined in a modular system. At the same time, this design not only allows the main functions to benefit from the advantages of CAN bus control, but also the auxiliary and supporting functions. This makes the use of MICK particularly advantageous in mobile machines with several consumer groups that work sequentially and are actuated separately from each other.

The directional control valve block type MICK is based on the proven directional spool valve type PSL according to the load-sensing principle from HAWE Hydraulik. The directional spool valve controls the volume flow steplessly and independently of the load. The integrated hydraulic safety circuit ensures that the three cylinder groups are separated from each other and prevents individual mast and support functions from being accidentally actuated at the same time. This block with two redundant shut-off paths thus offers the prerequisite for meeting modern safety requirements in mobile machinery. Designed in HAWE Hydraulik's proven modular system, this modular control block offers a wide range of variants and combination options. With its low pressure loss (keyword: delta p), it also represents a very energy-efficient control system, which is of interest for electrification projects in mobile machinery. Automation is also supported via the CAN bus control of all functions, the main and auxiliary functions.

Visit HAWE at bauma in Munich from April 7-13 at booth 348 in hall A3 to learn more about the MICK control block.