#Product Trends

Hiller lysate technology

for mechanical disintegration of waste activated sludge

1. OPERATING PRINCIPLE OF THE HILLER LYSATE TECHNOLOGY

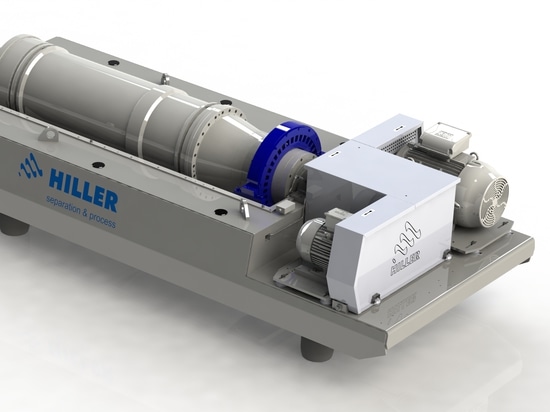

The mechanical cell disintegration of waste activated sludge using Hiller lysate technology optimizes the anaerobic sludge treatment in wastewater treatment plants.

This is achieved by installing a so-called lysing device at the decanter discharge.

It is a combination of knives which circulate in a housing with dies. The thickened sludge is led through between the knives and the dies. In doing so the cells of the microorganisms are either destroyed directly or the cell membrane is damaged to such an extent that cell fluid escapes. .

In practice this cell disintegration has already been proven several times. The cell disintegration can be determined with the so-called COD digestion degree. It is a measure for the increase of the free COD and is typically in the range of 3 to 6% for lysate centrifuges. Also in the DWA advisory leaflet M 302 the LYSAT technology is listed as a method with simple cell disintegration.

Two advantages are inherent in the system: 1. the whole waste activated sludge is disintegrated – not only a partial flow. 2. The centrate is not changed, as this is discharged before.

2. NEW APPROACH TO THIS PROVEN TECHNOLOGY: REDUCTION OF VISCOSITY

By using the lysate technology the viscosity of the waste activated sludge is influenced extremely positive and permanently reduced. Practical experiences at several WWTP’s has shown that the disintegrated sludge remains pumpable with the existing pump technology up to a solids concentration of 10%. Special high-pressure piston pumps or similar are not necessary. A concentration of 10% almost doubles the solids concentration in the digester.

As soon as the waste activated sludge with a higher solids concentration can be pumped into the digestion tank, new ways for energy saving and optimization in anaerobic stabilization of the sewage sludge open up.

Furthermore the energy for heating the digestion tank is used specifically to heat up the sludge and not to heat up the water.

An increased solids content in the digestion tank requires that the installed stirring or circulation units can cope with the higher solids content.

Here, systems such as gas injection or the digested sludge mixer (screw pumps) are advantageous over external recirculation by means of a pump

3. ADVANTAGES FOR ANAEROBIC SLUDGE TREATMENT AT SMALL AND MEDIUM-SIZED WASTEWATER TREATMENT PLANTS

At present, new anaerobic sludge treatment systems such as high-load digestion or two-phase digestion are moving into the focus of operators of wastewater treatment plants.

The lysate technology is particularly suitable for such systems, as these systems operate the digestion tanks with increased solid concentrations.

4. UPGRADING OF EXISTING DIGESTION TANKS OF CONVENTIONAL DESIGN

As experience with some existing wastewater treatment plants has shown, the higher solids concentration also helps to increase the digestion load in conventional digestion tanks.

In one case the construction of a third digestion tank could be postponed for years. The population growth and the settlement of industry led to a continuous increase in connection values. Until the construction of the third digestion tank, this was taken into account by increasing the solids concentration in the two existing digestion tanks.

In existing digestion tanks, the higher solids concentration extends the digestion time per se. This leads to an improved reduction of the organic matter and consequently to a higher dewatering capacity of the dewatering unit downstream of the digestion tower.

5. GENERAL INFORMATION ON LYSATE TECHNOLOGY AND REFERENCES

The lysate technology was first used at the Prague wastewater treatment plant in 1997 and has been successfully in operation there for more than 21 years. Extensive operating experience is available in many cases, including from the sewage treatment plants in Germany - Fürth, Wasserburg and Fürstenfeldbruck.

Following a public tender based on economic evaluation criteria, the Nuremberg municipal sewage treatment plant also decided to install a plant for mechanical waste activated sludge thickening with HILLER centrifuges and integrated lysing device. The project with two thickening decanters for throughputs of up to 90 m3/h each is in the planning phase and is scheduled to be commissioned in autumn 2020.

Simple retrofitting of the technology and almost no wear and tear

The wear is usually limited to the replacement of the knives. There is more than two decades of operating experience in this field.

Retrofitting to HILLER thickening centrifuges is also possible and can be flexibly mounted or dismounted without making any real changes to the decanter. Normally, the sizes of the electric motors installed on the thickening centrifuge are sufficient to cover the energy requirement.

6. THICKENING WITH CENTRIFUGES CHEAPER THAN OTHER SYSTEMS

Recently, centrifuges have been increasingly used to thicken waste activated sludge. Several comparative tests on wastewater treatment plants of all sizes have shown that the operating costs of thickening centrifuges are significantly lower than those of competing systems such as belt thickeners or disc thickeners.

These advantages in operating costs are achieved through three measures:

1. A so-called co current scroll is installed. This design achieves optimum separation efficiency. The less waste activated sludge is returned to the activated sludge system, the less additional ventilation is required. This saves energy in supplying the biology with air.

2 A very small amount of polymer (pFM) is dosed. The dosage is usually in the range of 0.5 to 1.0 kg active ingredient of the pFM per ton dry substance. Powdered pFM or an alternative flocculant, e.g. based on starch, can also be used. This allows the bowl speed to be reduced to a minimum. The bowl speed has the greatest influence on the energy consumption of a thickening centrifuge.

3. A larger part of the drive energy is recovered. By using the so-called EcoJet weir plates, which operate according to the recoil principle, a recuperation of up to 30% can be achieved.

A general advantage of the thickening centrifuges is that the degree of thickening of the waste activated sludge can be adjusted at will. The operator can adjust the DS content to his process by simply changing the differential speed, up to 20% is possible.