#Industry News

9 Types Of Metal Stamping Processes

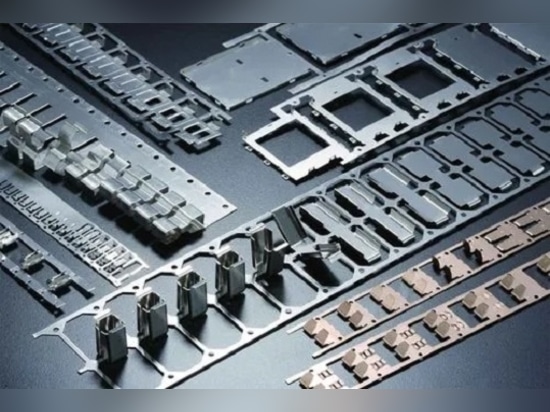

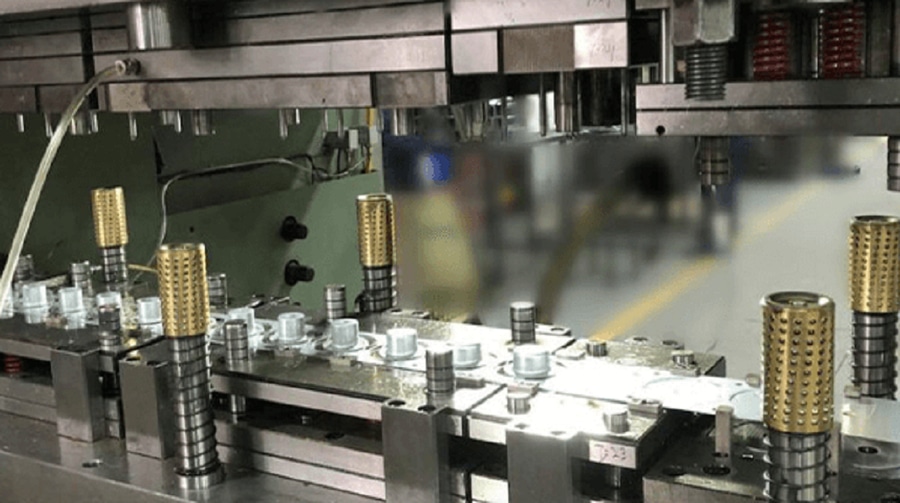

Metal Stamping Processes

Metal stamping is a manufacturing process that applies force to a metal sheet to deform it into a desired shape.

This process usually involves blanking, punching, coining, bending, flanging, stretching, embossing, curling, grooving on the metal.

1. Blanking refers to cutting a metal sheet through a mold to cut out a flat shape or outline. Typically used to produce flat parts or blanks that undergo further processing, such as forming or bending.

2. Punching is the application of pressure on a metal plate through a specially designed mold to form a hole in the desired shape. It is often used to manufacture through-holes or specific functional holes in parts to produce parts with various hole shapes, such as ventilation holes. bracket or panel.

3. Bending refers to the process of bending a metal plate into a desired shape or angle through a mold. This process applies bending force to the metal plate, causing the metal plate to bend and deform under the action of the mold. Bending is one of the common operations in metal stamping. It is widely used to manufacture various parts and products, such as boxes, casings, brackets, etc., to provide the required shape and structure for metal products.

4. Stretching refers to the process step of stretching a metal plate through a mold to form a deep or complex concave shape. This process applies tensile force to the metal plate, usually using a stretching mold, so that the metal plate is stretched and deformed under the action of the mold, usually into a cylindrical or cup shape. Such as the manufacture of products such as cups, cans and deep-drawn containers, where depth is the main requirement.

5. Coining is the creation of fine details, patterns, or textures on the surface of hardware. Such as adding decorative features, logos or textures to parts commonly used in coins and jewelry.

6. Imprinting is raising or recessing specific areas of metal to create a corresponding design or pattern. Product surfaces can be decorated, such as logos on nameplates, decorative patterns on car panels or textures on appliance covers.

7. The main characteristic of flanging is the formation of a raised, flat edge on a sheet metal part. Creates an edge with added strength or stiffness, often found in panels or enclosures.

8. Bending is rolling the edge of a metal piece into a round or arc shape. Generally, products that require rounded edges for safety or sealing purposes, such as parts such as formed cans, lids, or pipes.

9. The main feature of grooving is cutting a small V-shaped notch or groove out of the metal sheet. Typically used where two pieces of metal need to interlock or join, such as creating tabs and notches for assembly.

For more detailed information, including their definitions, advantages, and comparisons, you can click on the link below.